_________________________________________________________________________________________

www.schunk.de

XND.00018.002_A – 10/2018

25

5

Servicing, cleaning, maintenance

No special servicing is required, the spindle unit is protected by the carriage construction.

Lubricate the threaded profile and the contact surfaces regularly with machine oil, e.g. with

MOTOREX Supergliss 68 K to ISO VG 68.

Dismantle the clamping jaw from time to time and lubricate the thread of the threaded

spindle with grease.

5.1

General cleaning / lubrication

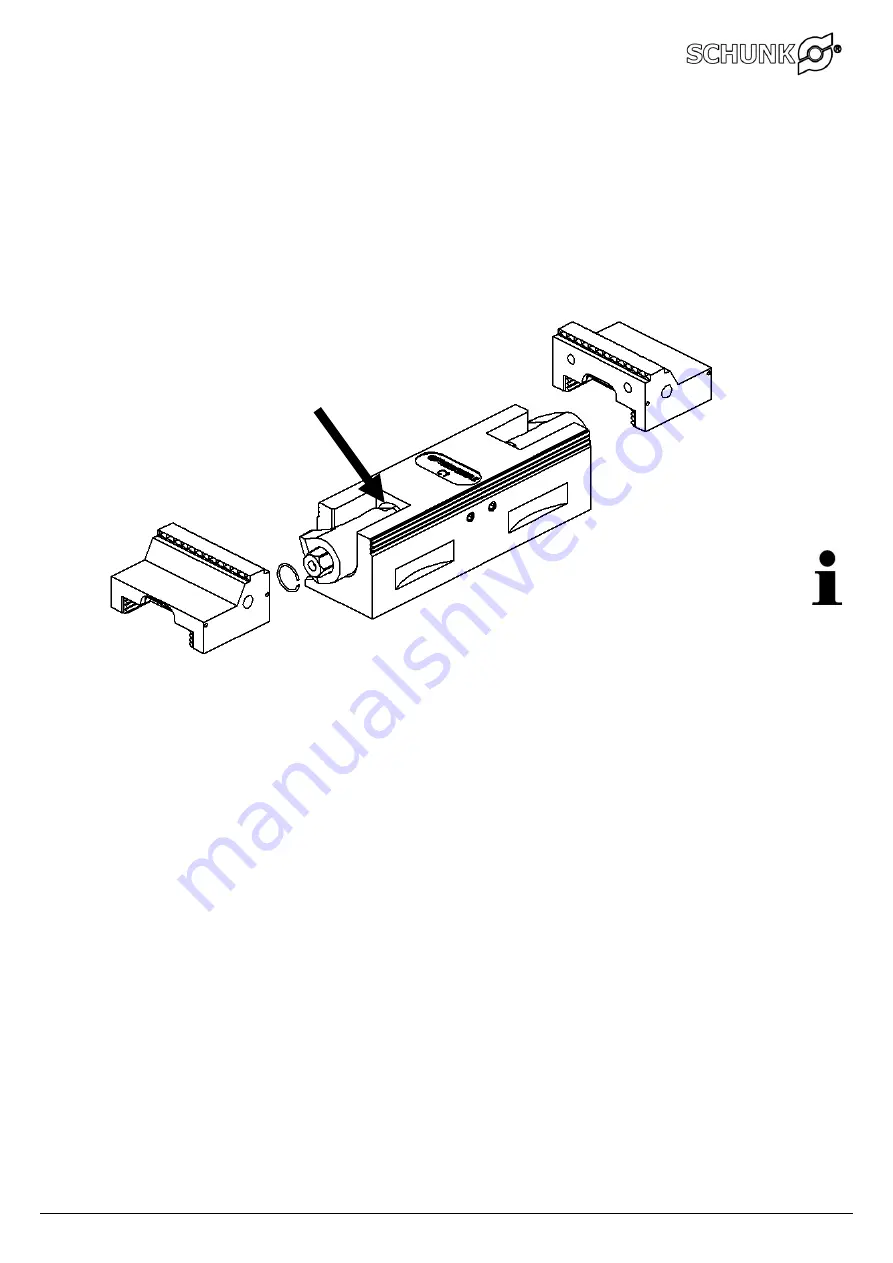

Disengage both clamping jaws (item 20)

from the drivers (items 40/50) using the

opener and turning the spindle to the left.

Open the vice until the drivers (items 40/50)

can be moved to the side.

Remove the clamping jaws (item 20) from

the tool body.

Remove the circlip (item 120) - do not lose!

Continue to open the vice until the

threaded spindle (item 30) can be seen

through the greasing recess.

Lubricate the thread through the greasing

recess.

Oil the contact surfaces, , e.g. with

MOTOREX Supergliss 68 K to ISO VG 68.

Re-assemble the unit (see page 28).

6

Troubleshooting, eliminating faults

Vice is hard to operate

Dismantle, clean and damaged surfaces must be carefully levelled off with a honing stone.

Recess for grease