_________________________________________________________________________________________

schunk.com

XND.00005.022_A – 10/2018

30

3

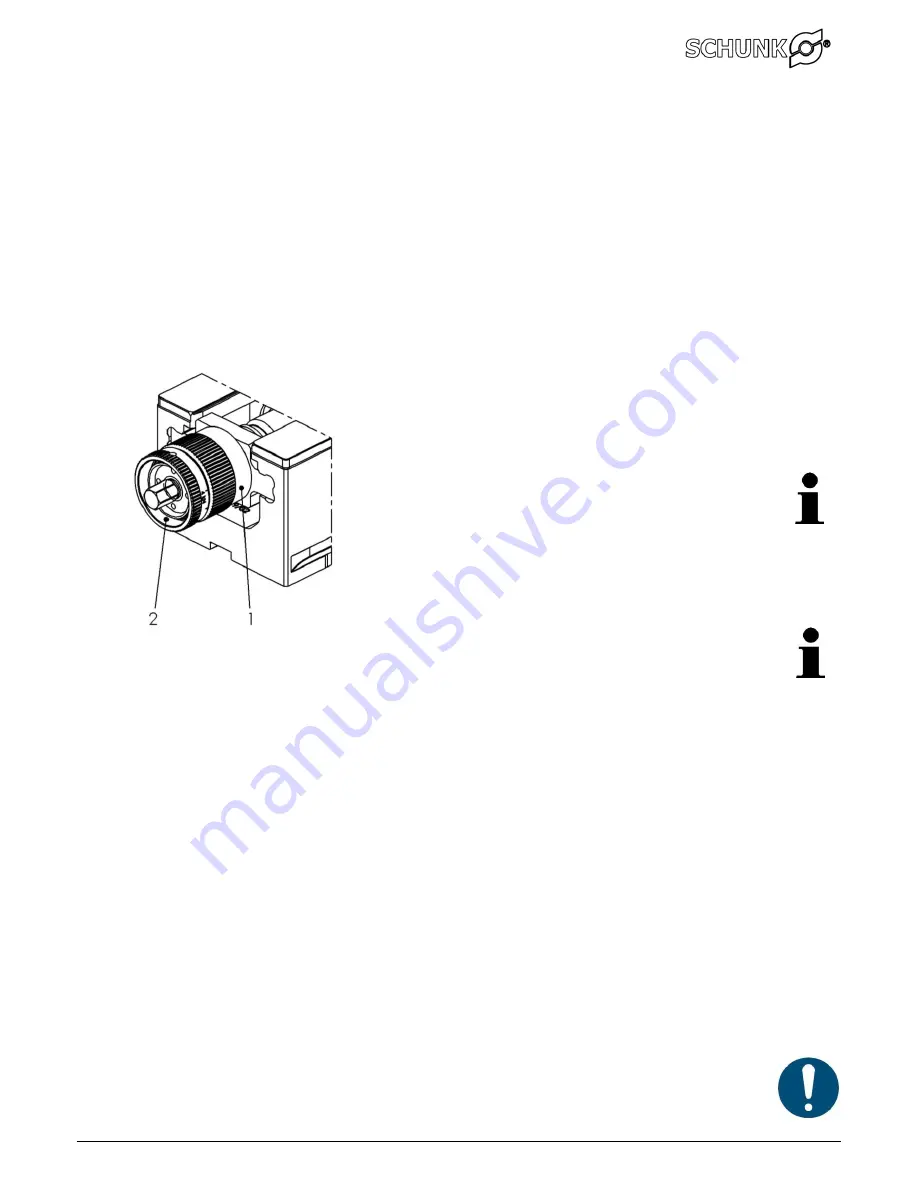

Description of the clamping device

The KSG has been designed for clamping raw parts and finished workpieces.

A wide range of accessories ensures the versatility of the equipment.

The clamping force is generated mechanically via a mechanical force cassette and a spindle

assembly. A setting ring is used for adjusted the force and the clamping force is achieved by

turning the clamping lever by 160°.

Mounting and removing the KSG is quick and easy.

3.1

Applications

3.1.1

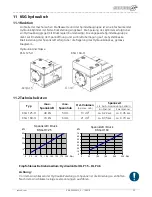

Adjusting the clamping range

Use the clamping lever to position the hexagon

head of the spindle to the left stop.

Adjust the clamping width with the knurled knob.

(1) (the lock will audibly engage)

Move the movable jaw to the workpiece so that

there is no play.

Serial production:

Turn the knurled knob three to four increments

backwards to create a gap of max. 2 mm to the

workpiece.

This means that the jaw opening is within the max.

closing range.

One-off production:

For one-off production a gap is not mandatory. By

pre-tensioning the workpiece manually using the

knurled knob, both the pre-tension and the final

force are increased.

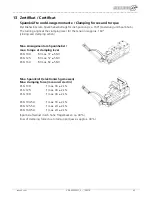

3.1.2

Clamping

Use the setting ring (2) to set the required clamping force.

Before clamping the workpiece, ensure that the vice is fixed and the clamping range

adjusted correctly.

Move the clamping lever to the 10 o'clock position.

By turning the clamping lever to the right by max. 90°, the moving jaw is moved to the

workpiece.

As the clamping lever is turned further by max. 70° the clamping force builds up. (more

force is needed to move the clamping lever as the force builds up)

When the clamping lever noticeably reaches the end stop, clamping has been completed

and the clamping force has been mechanically secured.

3.1.3

Releasing

Turn the clamping lever to the left; this will reduce the clamping force and then open the

closing range.

Ensure that the clamping lever comes to a stop at the left-hand stop.

Important: always keep a firm hold on the clamping lever handle while

operating it.