Assembly

26

09.00 | NSR maxi 220 / PKL maxi 220 | VERO-S robot coupling for pallet

handling | en | 0489051

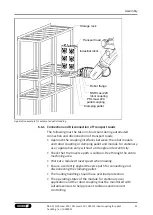

Only an original SCHUNK clamping pin may be mounted on the

coupling interface with the designated mounting screw. (The

screw must be tightened with the specified torque

).

Replacements can be supplied by SCHUNK.

NOTE

Check the screw fitting of the clamping pin on the pallet coupling

at regular intervals to ensure that it is secure. (The screws must be

tightened with the specified torque

).

The pallet coupling must always guarantee a completely flat work

surface at the robot coupling contact points. Design changes to the

pallet coupling by the operator are only permissible with the

approval of SCHUNK.

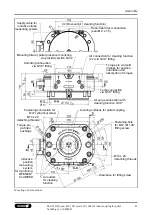

6.4.1 PKL maxi 220 Pallet Coupling

The PKL maxi 220 pallet coupling (ID no. 0471950) was designed as

a pallet changing interface for the NSR maxi 220 robot coupling.

play when joining with the robot module. The pallet coupling

provides the connection to the clamping pallet. The interface of

the pallet coupling has two cylindrical pins for position orientation

as well as four mounting screws for adapting the clamping pallet.

The clamping pallet to be installed is mounted on the pallet

coupling on the front face. The offset mounting screws replaced a

lower bracket for supporting purposes.

Four long cylindrical screws act as lag screws and guarantee a high

holding force and rigidity with heavy loading weights (see illustra-

tion "PKL maxi 220 pallet coupling"). The connection interface

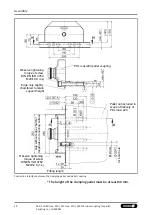

between the clamping pallet and pallet coupling is shown in the

"Connection interface between the clamping pallet and pallet

coupling" illustration.