Maintenance and Care

34

09.00 | NSR maxi 220 / PKL maxi 220 | VERO-S robot coupling for pallet

handling | en | 0489051

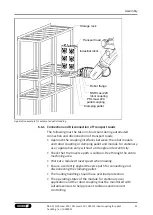

7.1 Regular Inspection of Robot and Pallet Coupling

A visual inspection of the robot coupling and the associated PKL

pallet coupling for possible damage to the components must be

carried out at regular intervals.

This visual inspection must be

carried out every 50,000 clamping cycles.

A leak test must be carried out on the robot coupling every

50,000 clamping cycles.

During a leak test, the air and plug-in connections, along with the

entire clamping system, are to be tested for leaks and significant

compressed air loss.

Test the robot coupling for leaks in both module positions.

To establish the tightness of the entire clamping system, no pallet

coupling should be connected.

If there are leaks in the clamping system, test the entire pneumatic

system (e.g. with Metaflux leak detection spray).

If any leaks are identified, check the seals and replace them if

necessary. Leaks at the plug-in connections or in the pneumatic

lines, for example, must be sealed and defective components

replaced.

Every 100,000 clamping cycles, the screw connections between

the robot coupling and the robot flange and the screw connections

from the pallet coupling to the clamping pallet must be checked

for secure fastening (see chapter Screw tightening

torques

After a collision (e.g. when connecting or disconnecting the

transport load), a visual inspection for possible damage to the

components is essential. Any damage such as cracks should be

identified.

If damage or signs of malfunctions are identifiable on any of the

components of the robot and pallet coupling, they may not be

restarted.

They can only be started up again once the faults have been

remedied, for example, by replacement of the damaged unit.