Sensors

12 Sensors

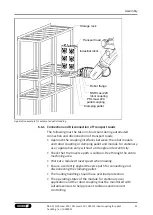

The quick-change pallet system NSR maxi 220 is prepared for using

the inductive stroke measuring system and the inductive proximity

switch NI 32 (see chapter "Coupling Interface"

• Information on handling sensors is available at schunk.com or

from SCHUNK contact persons.

• Technical data for the sensors can be found in the data sheets

(included in the scope of delivery or at schunk.com).

The proximity switch used has reverse polarity protection and is

short-circuit-proof.

For the proper use of the proximity switches, observe the

following:

• Do not pull on the cable of the sensor.

• Do not dangle the sensor from the cable.

• Do not excessively tighten the mounting screw or clips.

• Do not exceed the permissible bending radius of the cable (

☞

catalog specifications).

• Prevent proximity switch from coming into contact with hard

objects or with chemicals; in particular, nitric, chromic or

sulfuric acid.

Proximity switches are electronic components which can react

sensitively to high-frequency interference or electromagnetic

fields.

• Check that the cable is correctly connected and installed. There

must be sufficient distance between the switches and sources

of interference and their supply cables.

• Parallel switching of multiple sensor outputs of the same design

(npn, pnp) is permissible, though this does not increase the

permissible load current.

• Please note that the leakage current of the individual sensors is

accumulative (by about 2 mA).

43

09.00 | NSR maxi 220 / PKL maxi 220 | VERO-S robot coupling for pallet

handling | en | 0489051