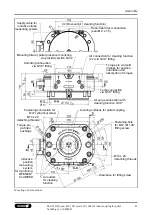

Assembly

6.1 Screw tightening torques

Screw tightening torques for mounting the pallet coupling on the

clamping pallet

(except the fitting for the clamping pin).

(Screw quality 10.9)

Screw size

M20

Screw tightening torques (Nm)

438

Screw tightening torques for mounting the robot coupling on the

robot flange. Screw tightening torques for mounting the quick-

change clamping pin on the pallet coupling.

(Screw quality 12.9)

Screw size

M12

M24

Screw tightening torques M

A

(Nm)

88

880

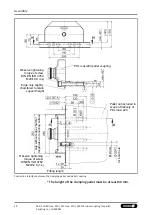

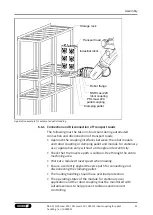

6.2 General Installation Notes

Request our installation drawings if doing the installation

yourself.

The NSR maxi 220 robot coupling is designed for heavy-load

industrial robots.

The robot coupling is used together with the pallet coupling for

work involving the transportation of heavy loading weights. A

robot coupling is mainly used as a single change interface.

If several linked clamping units are mounted, make sure that the

flatness and height deviation of the locating surfaces from module

to module (based on a 200 mm gage for bore holes) lies within

0.02 mm.

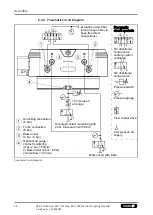

NOTE

When connecting the quick-change pallet systems, ensure that it is

only possible to completely ventilate the piston chamber via the

air connections during the locking process. The relevant valves or

shut-off valves should therefore be equipped with load relief. This

also applies to the turbo connection. It is vital that the turbo

connection be controlled in the NSR maxi 220 robot coupling in

order to ensure the required pull-in force at the coupling interface.

When disconnecting hose lines, the relevant openings must be

secured with locking plugs to prevent dirt or cooling lubricant from

entering.

If several units are activated via shared hose lines, feed lines with

the following minimum cross-sections must be used.

Number of modules

At least nominal hose width

1

4 mm

2, 3, 4

6 mm

19

09.00 | NSR maxi 220 / PKL maxi 220 | VERO-S robot coupling for pallet

handling | en | 0489051