Maintenance

10.00 | PGN-plus-P | Assembly- and Operating Manual | en | 389753

49

7.3 Lubricants/Lubrication points (basic lubrication)

SCHUNK recommends the lubricants listed.

During maintenance, treat all greased areas with lubricant. Thinly

apply lubricant with a lint-free cloth.

Lubricant point

Lubricant

Metallic sliding surfaces

microGLEIT GP 360

All seals

Renolit HLT 2

Cylinder surfaces

Renolit HLT 2

7.4 Lubricate product

WARNING

Risk of injury due to moving parts!

When moving the gripper fingers, body parts may get squashed/

hit causing severe injuries.

•

Do not interfere with moving parts during operation.

•

Observe position and direction of movement of the gripper

fingers.

Ø

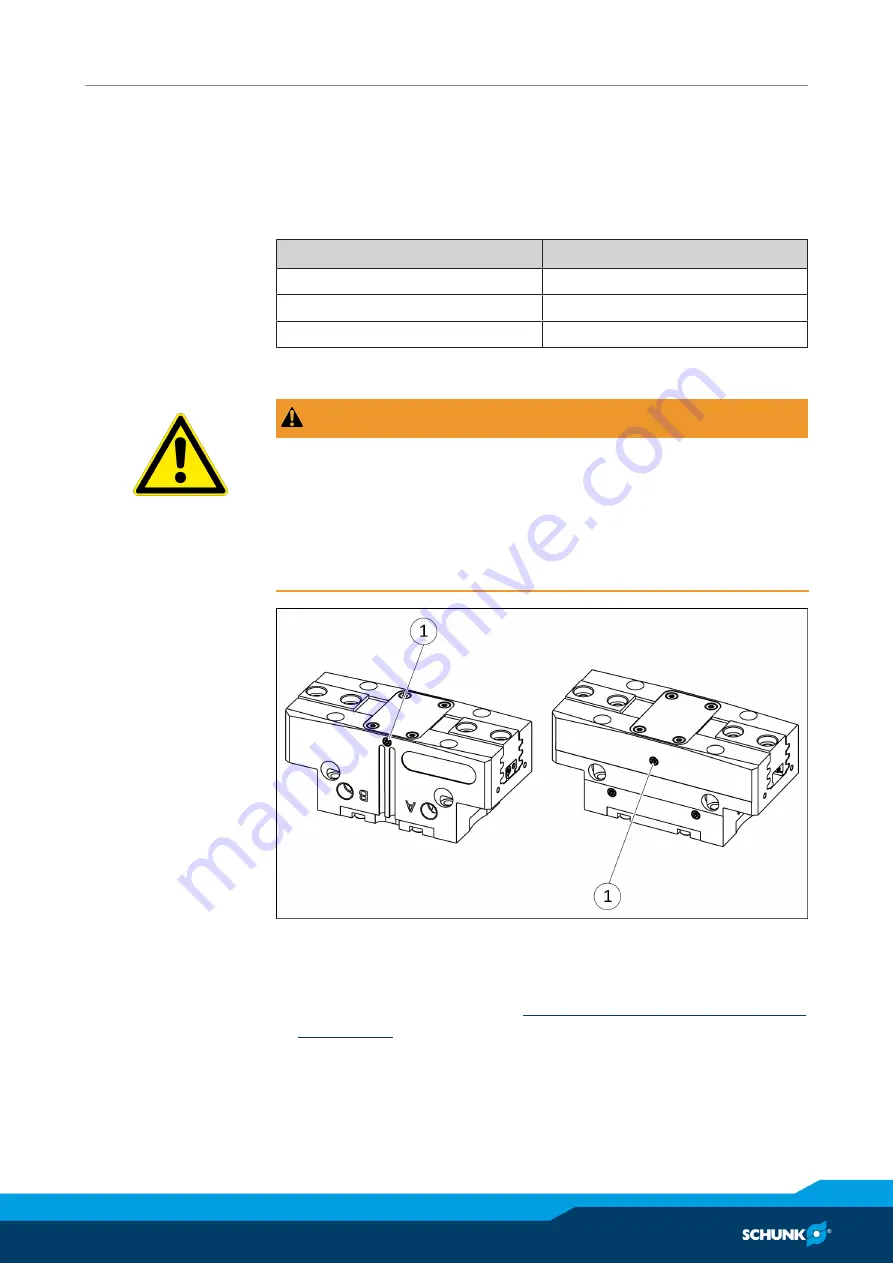

Remove set-screw on an air purge connection (1).

Ø

Screw in lubrication nipple.

Ø

Apply a layer of grease to metallic sliding surfaces of the gripper

using the lubrication nipple,

Lubricants/Lubrication points (basic

49].

✓

While lubricating, completely open and close the gripper

alternately.

Ø

Unscrew the lubrication nipple.

Ø

Screw set-screws into both air purge connections (1).