Function

32

03.00 | ROTA 2B | Assembly and operating manual | en | 0889059

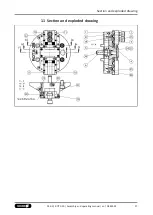

8 Function

8.1 Function and handling

The ROTA 2B wedge hook chuck is operated by circular full or

hollow clamp cylinder or static hydraulic cylinder. The axial tension

and pressure forces are converted via the wedge hook angle in the

piston and base jaw into radial chuck clamping force.

The chuck jaw clamping and opening movement is preset by the

clamping cylinder. The fine serrations on the base jaw are suitable

for standard jaws and special jaws for awkward workpiece shapes.

All ROTA 2B sizes can also be supplied with slot and tenon base

jaws (up to size 125 with slot and tenon only). The top jaws are

moved or changed with the clamps open.

ROTA 2B‘s long jaw stroke makes it particularly suitable for

bridging long travel distances from workpiece shapes to clamping

position. This makes this chuck especially appropriate for fittings

and cast components. ROTA 2B chucks installation height has been

improved (shorter).

8.2 Replacement or renewal of jaws

Clamping jaws for maximum clamping repeat accuracy have to be

bored out or ground out in the clamping chuck under clamping

pressure.

When boring or grinding out, ensure that the turning ring or bolt is

clamped by the

top jaw

- and not the base jaw.

Tighten jaw fastening screws (Screw-quality 12.9) to specified

torque

Tighten the jaw fastening screws with a dynamometric key.Never

use a pipe extension or hammer to tighten the screws with an

Allen key.