Attachment

7 Attachment

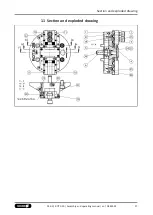

The item numbers specified for the corresponding individual

components relate to chapter drawings.

7.1 Pre-assembly measures

Carefully lift the product (e.g. using suitable lifting gear) from the

packaging.

CAUTION

Danger of injury due to sharp edges and rough or slippery

surfaces

Use personal protective gear, especially safety gloves.

Check the delivery for completeness and for transport damage.

7.2 Mounting of the Chuck to the Machine Spindle

Checking the chuck mounting Check the machine spindle head or

the finish machined adapter plate for concentricity and face

runout.

The permissible limit is 0.005 mm as per DIN 6386 and ISO 3089.

Completely remove cylinder screws (item 15) and the top.

For actuation of the clamping cylinder, please remove the drawbar

to its front position.

Push the chuck piston (3) into its foremost position.

CAUTION

No stop in front of the piston position

The adaptation between the drawtube and drawbar of the

machine and the chuck piston should be designed that in the stop

is in the clamping cylinder forwards. In the chuck is the stop

backwards. In Fig. 2, is the chuck marked in the maximum

possible front piston position in which the chuck piston not

strikes.

For questions regarding the piston position for self-installation,

contact our technical support service during our business hours.

27

03.00 | ROTA 2B | Assembly and operating manual | en | 0889059