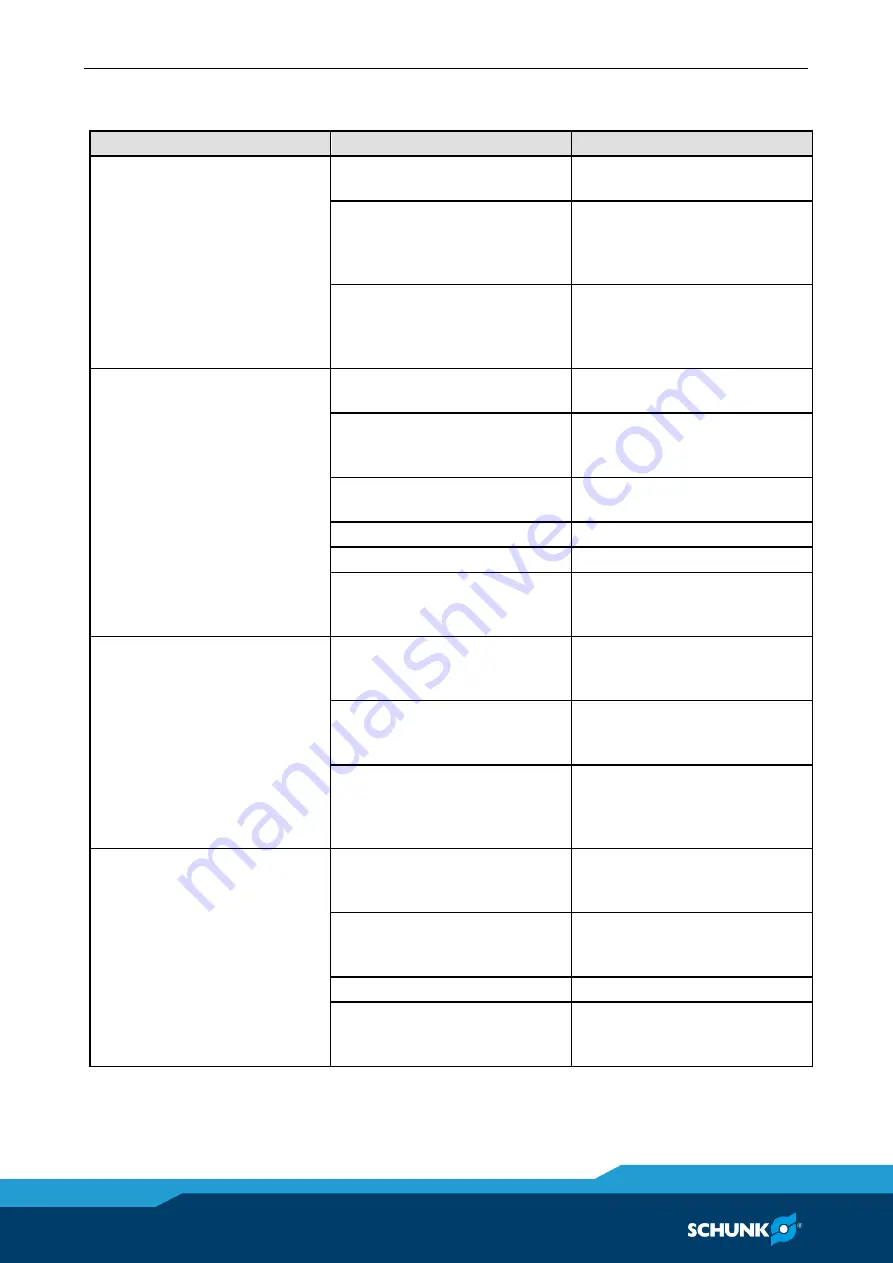

Remedies for faults

52

02.00|1416054_ROTA-M2 + 2 |en-US

Remedies for faults

Fault

Cause

Remedy

Actuation stiffness

Tightening torque of top jaws

too high

Use correct tightening torque

Damage to the guideways

Disassemble and check the

lathe chuck. Replace worn or

damaged parts with SCHUNK

spare parts

Drive spindle damaged (due

to overload)

Disassemble and check the

lathe chuck. Replace worn or

damaged parts with SCHUNK

spare parts

Concentricity error

Top jaws on incorrect base

jaw

Mount top jaws in correct

allocation

Allocation of the

components switched during

assembly

Disassemble the lathe chuck

and assemble it using correct

component allocation

Top jaws not correctly

turned/ground

Repeat turning/grinding

Dirty clamping faces

Clean the clamping faces

Dirty jaw interface

Clean the jaw interface

Compensation stroke

depleted in clamping

situation

Adjust position of top jaws to

workpiece geometry

Drop in clamping force

Lathe chuck lubrication

insufficient, maintenance

interval exceeded

Lubricate the lathe chuck, if

necessary, disassemble,

clean and relubricate

No stroke movement with

high repetition

Open and close the lathe

chuck several times without

workpiece

Components worn in the

force flow

Disassemble and check the

lathe chuck. Replace worn or

damaged parts with original

SCHUNK spare parts

Vibrations on machine

spindle

Compensation stroke

depleted in clamping

situation

Adjust position of top jaws to

workpiece geometry

Imbalance due to workpiece Compensate for imbalance

by adding weight to the

chuck body

Imbalance due to top jaw

Correct the top jaw position

Imbalance due to machine

spindle or flange/direct

mounting

Check components for

concentricity, align, balance

or replace if necessary

8