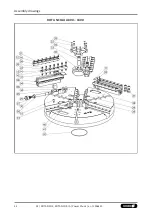

Mounting

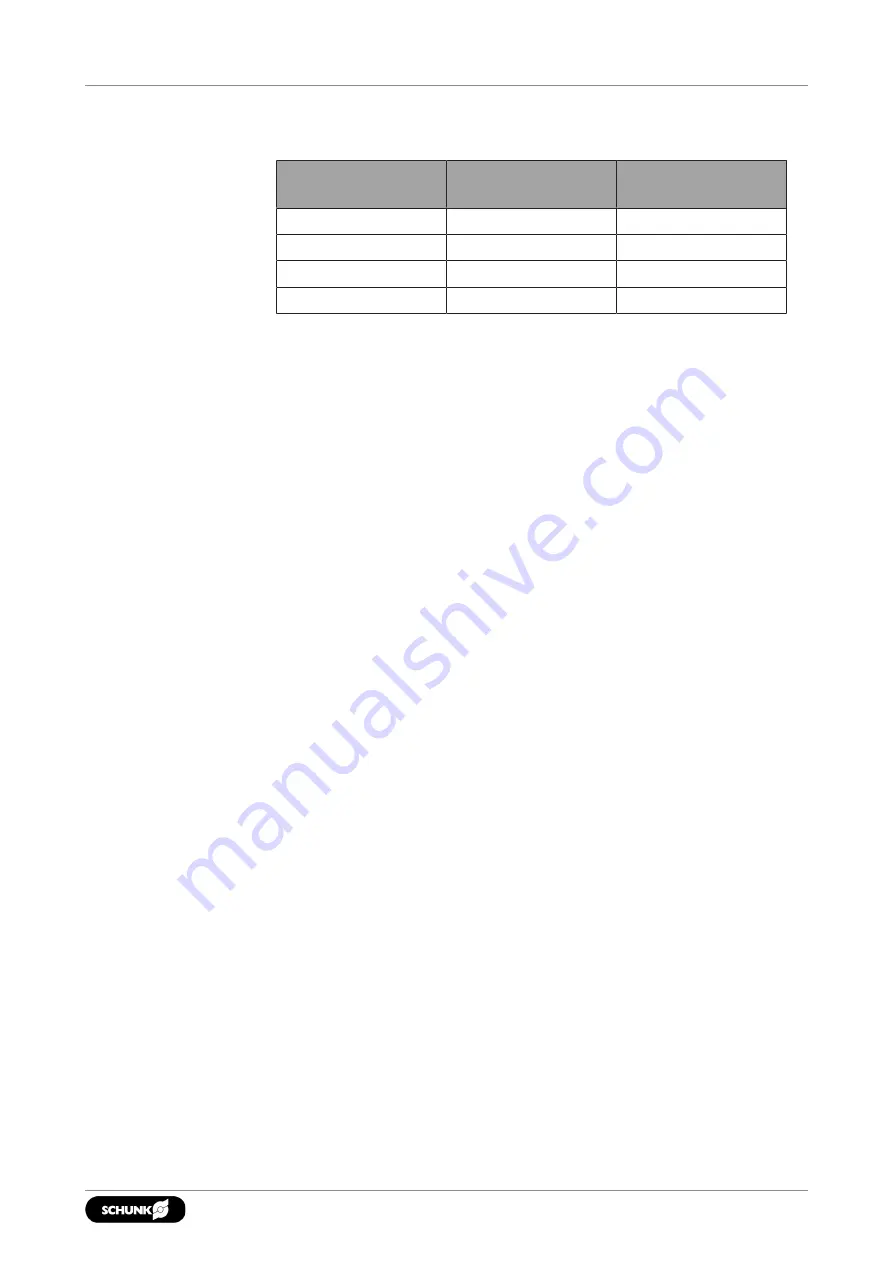

Maximum attainable radial and axial run-out tolerances related

to the chuck

Chuck size [mm]

Max. radial run-out

tolerance [mm]

Max. axial run-out

tolerance [mm]

800

0.06

0.05

1000

0.06

0.05

1200

0.08

0.06

1400

0.08

0.06

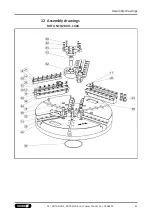

• Remove the top jaws with mounting screws and any T-nuts

from the base jaws.

• Move the draw bar to its foremost position by actuating the

clamping cylinder.

• Disassemble the cover.

• Push the chuck piston into the foremost position.

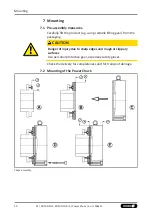

• In principle, it is possible to mount the chuck in two installation

positions (horizontal/vertical), depending on the position of the

machine spindle.

Horizontal mounting of the lathe chuck.

Vertical mounting of the lathe chuck.

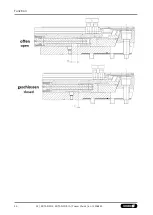

7.3 Horizontal attachment

Lift the chuck to the front of the spindle lug using eye bolts flush to

the center of the spindle.

•

ROTA NCO2 800 – 1400 & ROTA NCO2-JA 800 – 1400:

Turn the chuck on the spindle or machine table until the

mounting holes and spindle flange threads are aligned. Screw

the central mounting screw into the drawbar or the draw tube

adapter with a hexagon socket wrench until the stop.

7.4 Vertical attachment

•

ROTA NCO2 800 – 1400 & ROTA NCO2-JA 800 – 1400:

Turn the chuck on the spindle or machine table until the

mounting holes and spindle flange threads are aligned.

Screw the central mounting screw into the drawbar or the draw

tube adapter with a hexagon socket wrench until the stop.

• Mount the cover.

• Insert and

slightly tighten

the mounting screws.

• Check the chuck for radial and axial run-out and, if necessary,

align it at the outer diameter with gentle taps using a plastic

hammer. (See "Chuck assembly" Fig. - E and the table of the

attainable maximum radial and axial run-out tolerances in the

Assembly chapter)

31

01 | ROTA NCO2, ROTA NCO2-JA | Power Chuck | en | 1506425