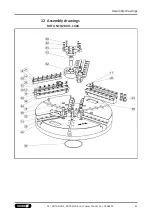

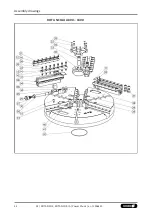

Maintenance

9 Maintenance

9.1 Lubrication

To maintain the reliable function and high quality of the lathe

chuck, it has to be regularly lubricated at the lubrication nipples

(items 25 and 26).

In order to achieve optimum grease distribution, the base jaws

need to be moved into the open position for O.D. clamping, the

power chuck lubricated, and the base jaws then closed again.

Repeat this procedure one more time.

Then the piston has to be moved several times up to its end

positions.

Operating conditions

Depending on the operating conditions, the function and clamping

force need to be checked after a specific period of operation (see

chapter "Maintenance intervals"

calibrated gripping force gauge for measuring during the clamping

force test (SCHUNK IFT).

Lubricate all three segments evenly in order to avoid large

imbalances.

Technical condition

With the smallest possible actuating pressure (hydraulic cylinder),

the base jaws should move evenly. This method only provides a

limited indication and is no substitute for measuring the clamping

force.

If the clamping force has dropped too much or if the base jaws and

piston no longer move properly, the chuck will have to be

disassembled, cleaned and relubricated.

Only use original SCHUNK spare parts when replacing damaged

parts.

9.2 Maintenance intervals

Lubrication of the grease areas:

Lubrication interval Strain

every 25 hours

normal / coolant utilization

every 8 hours

high / coolant utilization

after 1200 hours or

as needed

Total cleaning with disassembly of the

chuck, depending on type and degree of

contamination

9.3 Changing the top jaws

When changing the top jaws, the serration has to be cleaned and

greased with SCHUNK LINOMAX plus special grease.

37

01 | ROTA NCO2, ROTA NCO2-JA | Power Chuck | en | 1506425