Function

8 Function

The item numbers specified for the corresponding individual

components relate to chapter drawings.

8.1 Function and handling

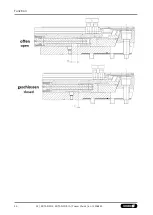

Wedge hook chuck are actuated by rotating cylinders with or

without through holes. The axial draw- or pressure forces are

deviated into a radial jaw clamping force via the helical angle of

traction between the piston and the base jaws.

The clamp and unclamping stroke of the jaws is determined by the

cylinder. Moving or changing the base jaws with top jaws bolted to

them must be carried out in unclamped position. For safety

reasons the base jaws are still interlocked when the chuck piston is

in this position. The base jaws are unlocked mechanically.

8.2 Change or supplement of jaws

Chuck jaws for maximum clamping repeat accuracy must be

turned or ground in the chuck under clamping pressure.

• When turning or grinding, ensure that the turning ring or

turning pin is clamped

by the top jaws

and not by the base

jaws.

• Keep the base jaws and top jaws screwed in place for recurring

work. Tighten the jaw mounting screws to the specified

torque.

Tighten the jaw mounting screws with a torque wrench. On no

account tighten the screws with an extension pipe or with

hammer blows.

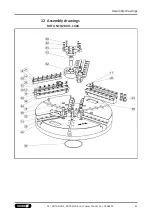

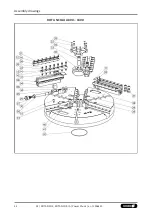

8.3 Disassembly of chucks for complete cleaning or in case of

damage

The item numbers specified for the corresponding individual

components relate to chapter drawings.

The tightening torques for all screws must be observed during

every assembly and disassembly!

The chuck can only be disassembled once it has been removed.

• Remove the top jaws (if present), T-nuts, and mounting screws

from the base jaws.

• Remove screws (item 20) and covers (item 11) from the base

jaws.

• Unscrew the cover plate (item 28) screws on the cover (item 22)

from the chuck and remove the cover (item 3).

• Remove the central mounting screw M36x90.

• Remove all cover plates (item 28) in the chuck and unscrew the

screws (item 22).

33

01 | ROTA NCO2, ROTA NCO2-JA | Power Chuck | en | 1506425