Attachment and disassembly of the chuck

01.00|ROTA THWplus |en

29

with a depth gauge

R2 = R1 + 0.3 mm (max. + 0.5 mm)

You have to ensure that the piston can be moved to the foremost

(jaw change) position. To do this, ensure that the dimensions for

the attachment (see Fig. 2) are complied with.

• Move the chuck piston (item 3) to its foremost position.

Chucks in sizes 165, 185 and 215

• Offset the base jaws so that they do not project over the outer

edge of the chuck.

• The entire chuck has to be rotated on the draw tube (rod).

• Alternately tighten the mounting screws supplied to fix the

chuck to the spindle nose.

• Check radial and axial runout at the checking edge.

• Check the function and the size of the operating force.

• Move the cylinder into the front position. Unlock the wedge

bars with the jaw change key supplied and insert or offset the

base jaws into the chuck's jaw guidance as shown on markings

1, 2 or 3.

• Check that the base jaw and jaw stroke are easy to move.

Chucks in sizes 260 and 315

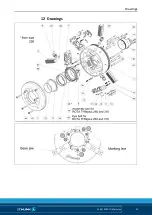

• Offset the base jaws to the outermost marking (see drawings,

chapter 11).

• Remove the screws (item 43) and use the threaded extraction

hole to push off the protection sleeve (item 4) away from the

chuck body (item 1), and then pull it out completely.

• Lift the chuck to in front of the spindle lug using an eye bolt

flush to the center of the spindle.

• Screw the rotating center sleeve (item 18) onto the draw tube

using the enclosed assembly tool as far as this will go.

• Alternately tighten the mounting screws supplied to fix the

chuck to the spindle nose.

• Check radial and axial runout at the checking edge.

• Check the function and the size of the operating force.

• Insert and fasten the protection sleeve (item 4) in the chuck

body with the screws (item 43).

• Move the cylinder to the front position. Unlock the wedge bars

with the jaw change key supplied and insert or offset the base