Attachment and disassembly of the chuck

30

01.00|ROTA THWplus |en

jaws into the chuck's jaw guidance as shown on markings 1, 2

or 3.

• Check that the base jaw and jaw stroke are easy to move.

Dismounting of the spindle is carried out in reverse order.

At regular intervals, check that the retainer ring (item 17) is seat-

ed firmly (see Fig. 3).

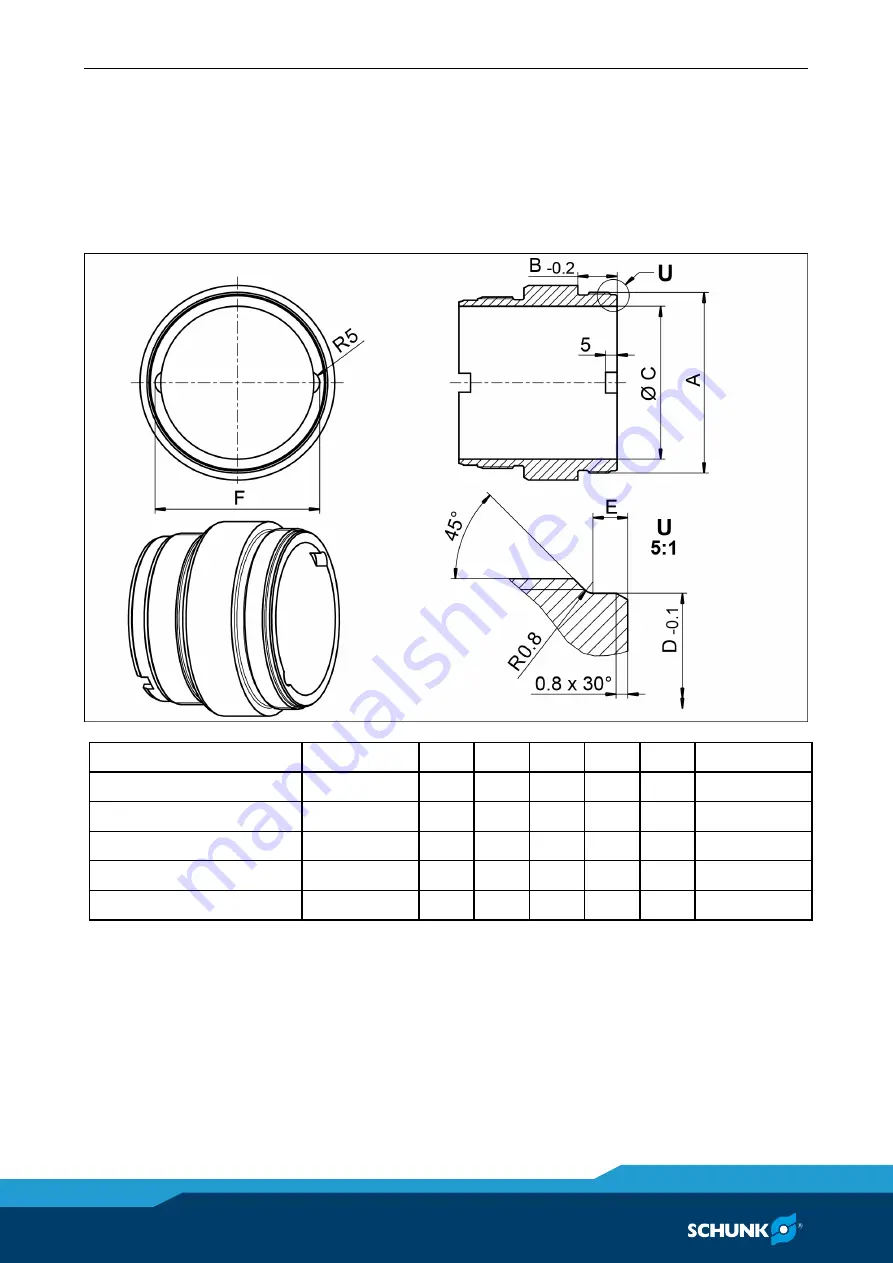

A

B

C

D

E

F

O-ring

ROTA THW plus 165-43 M54 x 1.5

15.0 43

50.8 2.8

47

50.47 x 2.62

ROTA THW plus 185-52 M64 x 1.5

15.0 52

62.0 2.4

58

60 x 2

ROTA THW plus 215-66 M78 x 1.5

17.0 66

76.0 2.4

70

76 x 2

ROTA THW plus 260-81 M90 x 2.0

20.3 81

87.0 2.4

84

86 x 2

ROTA THW plus 315-104 M115 x 2.0 22.5 104 110.0 3.2

107 110 x 3

Lubricate before commissioning the chuck

Before commissioning, move the chuck in the open position. Press

three strokes SCHUNK special grease LINOMAX into each of the

grease nipples using a high-pressure grease gun. To achieve the

optimal grease distribution and the maximum clamping force,

close and open the chuck several times over the entire clamping

stroke. Check the clamping force and, if necessary, repeat the lu-

brication process.