Assembly

5.3 Checking the chuck mount

The machine side must be aligned prior to the flange being

installed in order to achieve high run-out accuracy of the chuck.

To do this, check the contact surfaces on the spindle for axial and

radial run-out accuracy using a dial indicator.

There should be a maximum concentricity error in the centering

of the mount of 0.01 mm and a maximum axial run-out error in

the contact surfaces of 0.01 mm. The flat surface of the spindle

must also be checked for flatness using a straight edge.

Make sure that the surface area of the flat surface is deburred at

the bore holes and is clean.

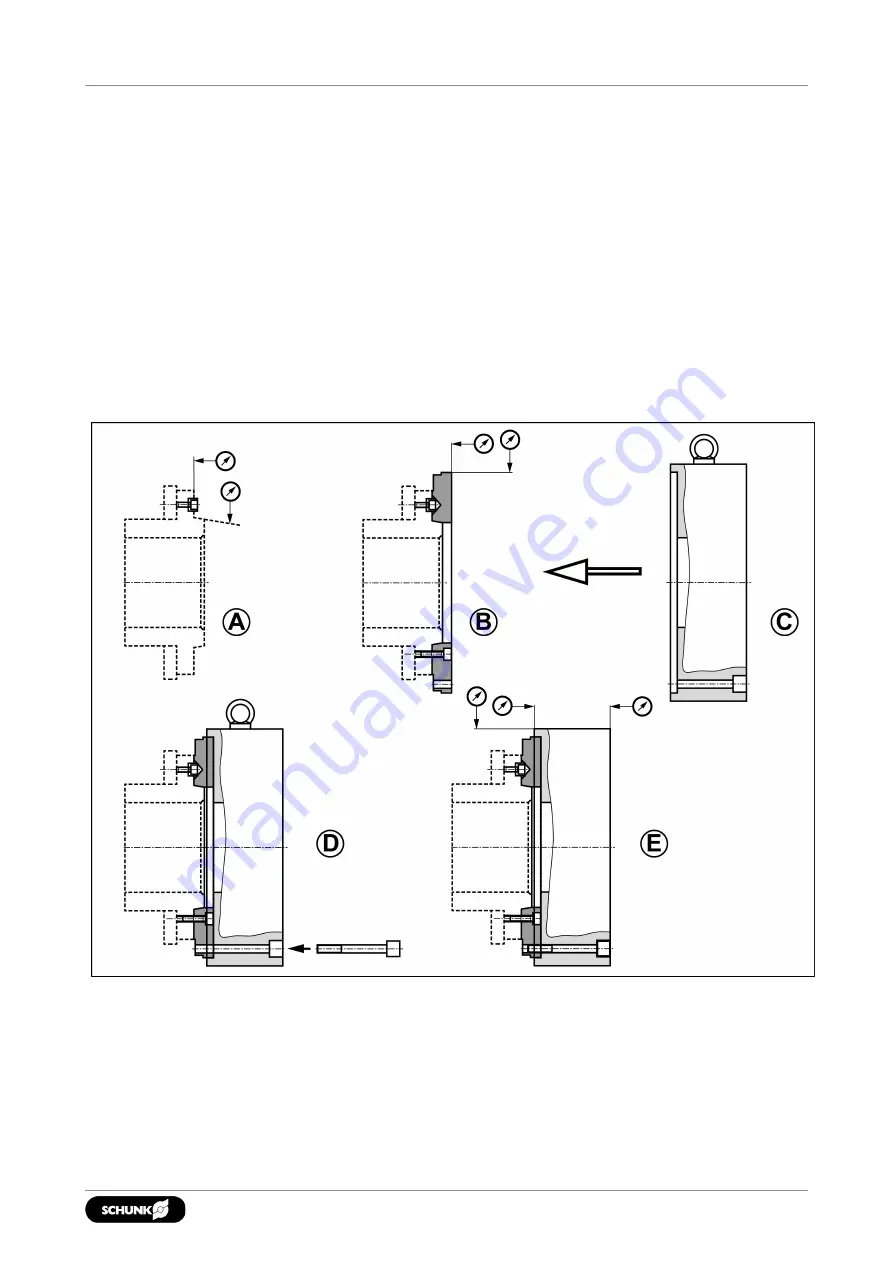

5.4 Assembly

Lathe chuck assembly

•

Chuck assembly (with cylindrical recess)

✓

Assembly preparation for the chuck with reduction or

expansion adapter plate

29

06.00 | ROTA THW3 | Power Chuck | en | 1440828

Summary of Contents for ROTA THW3

Page 1: ...Translation of Original Operating Manual Power Chuck ROTA THW3 Assembly and Operating Manual ...

Page 46: ...Drawing 46 06 00 ROTA THW3 Power Chuck en 1440828 9 Drawing Full chuck Accessories ...

Page 47: ...Drawing Thrust jaw 47 06 00 ROTA THW3 Power Chuck en 1440828 ...

Page 48: ...Drawing 48 06 00 ROTA THW3 Power Chuck en 1440828 Mount ...

Page 49: ...Drawing Thread lock with Klemm tight 49 06 00 ROTA THW3 Power Chuck en 1440828 ...

Page 54: ......

Page 55: ......