Technical data

20

01.00|ROTA THW vario |en-US

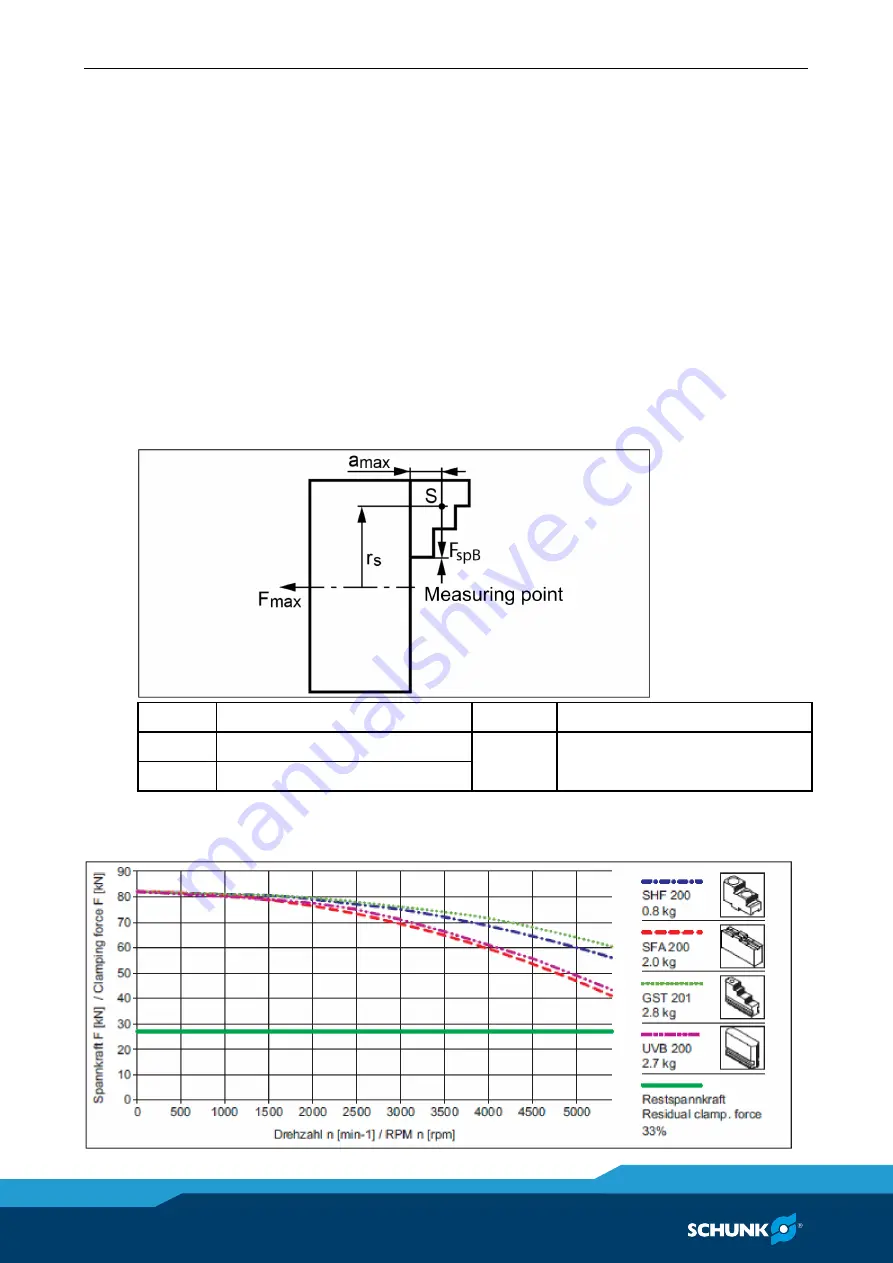

Clamping force RPM diagrams

The diagrams relate to a 3-jaw chuck.

Clamping force/RPM curves have been determined by using hard

jaws. In the determination process, the maximum actuating force

was applied and the jaws were set flush with the outer diameter of

the chuck.

The chuck is in perfect condition and lubricated with SCHUNK

LINOMAX special grease.

If one or more of these prerequisites is modified, the graphs will

no longer be valid.

Chuck setup for clamping force/RPM diagram

F

spB

Jaw clamping force

S

Center of gravity

r

s

Center of gravity radius

a

max

Max. jaw eccentricity of center

of gravity in axial direction

F

max

Max. actuating force

Clamping force RPM diagram for ROTA THW

6.2

Summary of Contents for ROTA THWvario

Page 60: ...Assembly drawing 60 01 00 ROTA THW vario en US Assembly drawing ROTA THW vario 215 62 13 13 1 ...

Page 61: ...Assembly drawing 01 00 ROTA THW vario en US 61 ...

Page 62: ...Assembly drawing 62 01 00 ROTA THW vario en US Segmented mandrel ROTA THW vario D 13 1 1 ...

Page 63: ...Assembly drawing 01 00 ROTA THW vario en US 63 Collet chuck ROTA THW vario F 13 1 2 ...