Assembly

01.00|ROTA THW vario |en-US

41

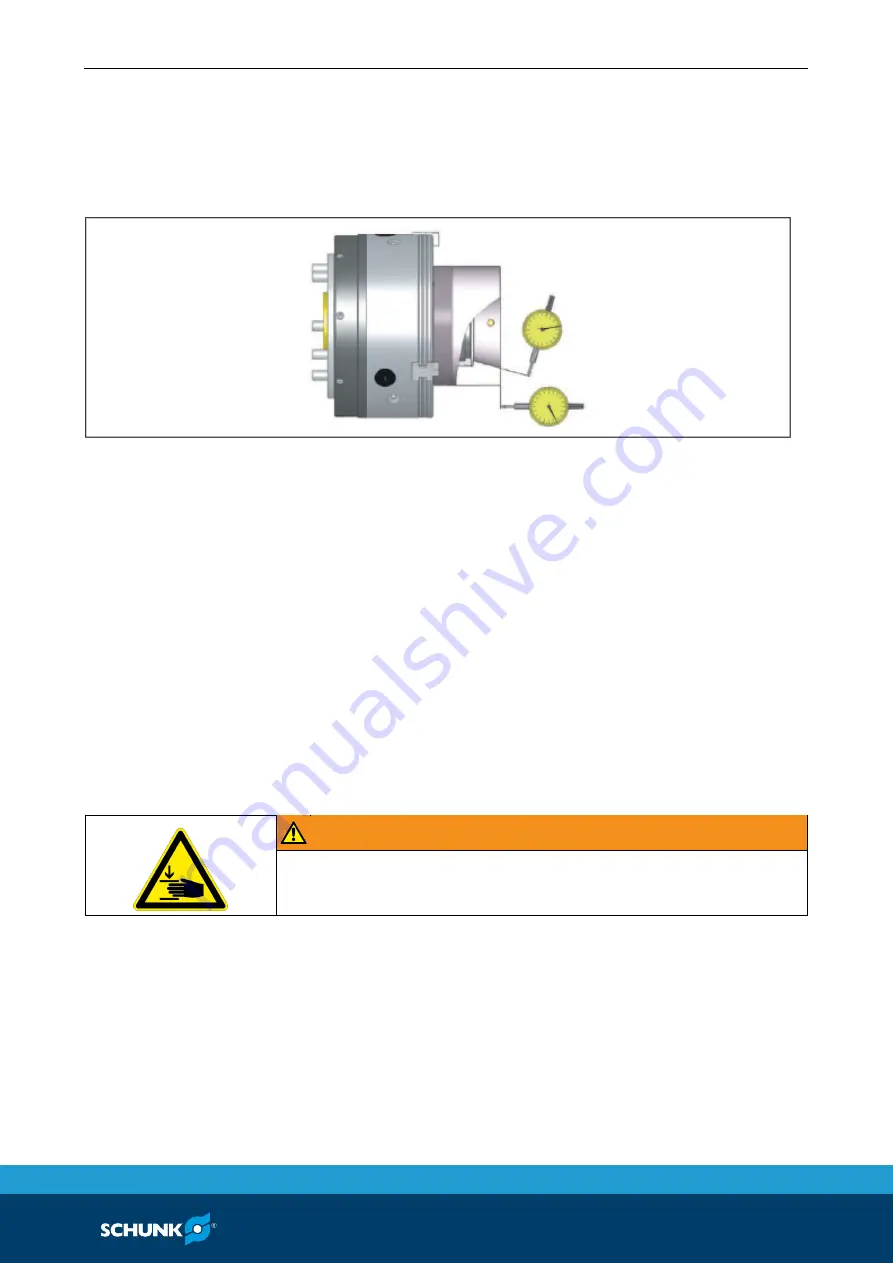

Furthermore, concentricity can only be achieved by improved

alignment of the power chuck.

If necessary, the mounting position of the vario F must be marked

to a specific position to achieve optimum repeat clamping

accuracy.

Replacing vario F clamping head

The clamping head can only be changed in the release position of

the power chuck. Before replacing a clamping head (item 1), clean

the clamping taper in the chuck body (item 2). Place the changing

device on the clamping head. Insert the axis-parallel pins of the

changing device completely into the frontal changing bores of the

clamping head. By actuating the changing device, the clamping

head (item 1) is compressed in the coupling area. Insert the

clamping head into the chuck body with the fixing bolts (item 6)

engaging in the milled fixing grooves (item 17) in the segment

centers (never in the vulcanized slots).

Use slight pressure to loosen and pull out the changing device in

the spindle direction.

WARNING

When operating the changing device, do not reach into the

moving parts due to the risk of crushing.

Remove the SPANNTOP clamping head

The clamping head can only be removed in the release position of

the chuck. Place the changing device on the clamping head. Insert

the axis-parallel pins of the changing device completely into the

front changing bores of the clamping head. By actuating the

changing device, the clamping head (item 1) is compressed in the

coupling area. Remove the changing device with the clamping

head from the lathe chuck, loosen the changing device and

remove the clamping head.

8.3.2

Summary of Contents for ROTA THWvario

Page 60: ...Assembly drawing 60 01 00 ROTA THW vario en US Assembly drawing ROTA THW vario 215 62 13 13 1 ...

Page 61: ...Assembly drawing 01 00 ROTA THW vario en US 61 ...

Page 62: ...Assembly drawing 62 01 00 ROTA THW vario en US Segmented mandrel ROTA THW vario D 13 1 1 ...

Page 63: ...Assembly drawing 01 00 ROTA THW vario en US 63 Collet chuck ROTA THW vario F 13 1 2 ...