Maintenance

52

01.00|ROTA THW vario |en-US

Cleaning

NOTICE

Material damage due to cleaning with compressed air!

Cleaning the adaptation clamping device with compressed air can

cause metal chips to settle in threads and grooves. This can

damage or even destroy the clamping device.

• Never clean adaptation clamping devices with compressed air.

Required supplies:

• ester-free, non-polar detergent

• soft, lint-free cloth

Clean all components with detergent and cloth to remove all oil

and grease residues.

Lubrication

WARNING

To maintain the safe function of the lathe chuck, it has to be

regularly lubricated.

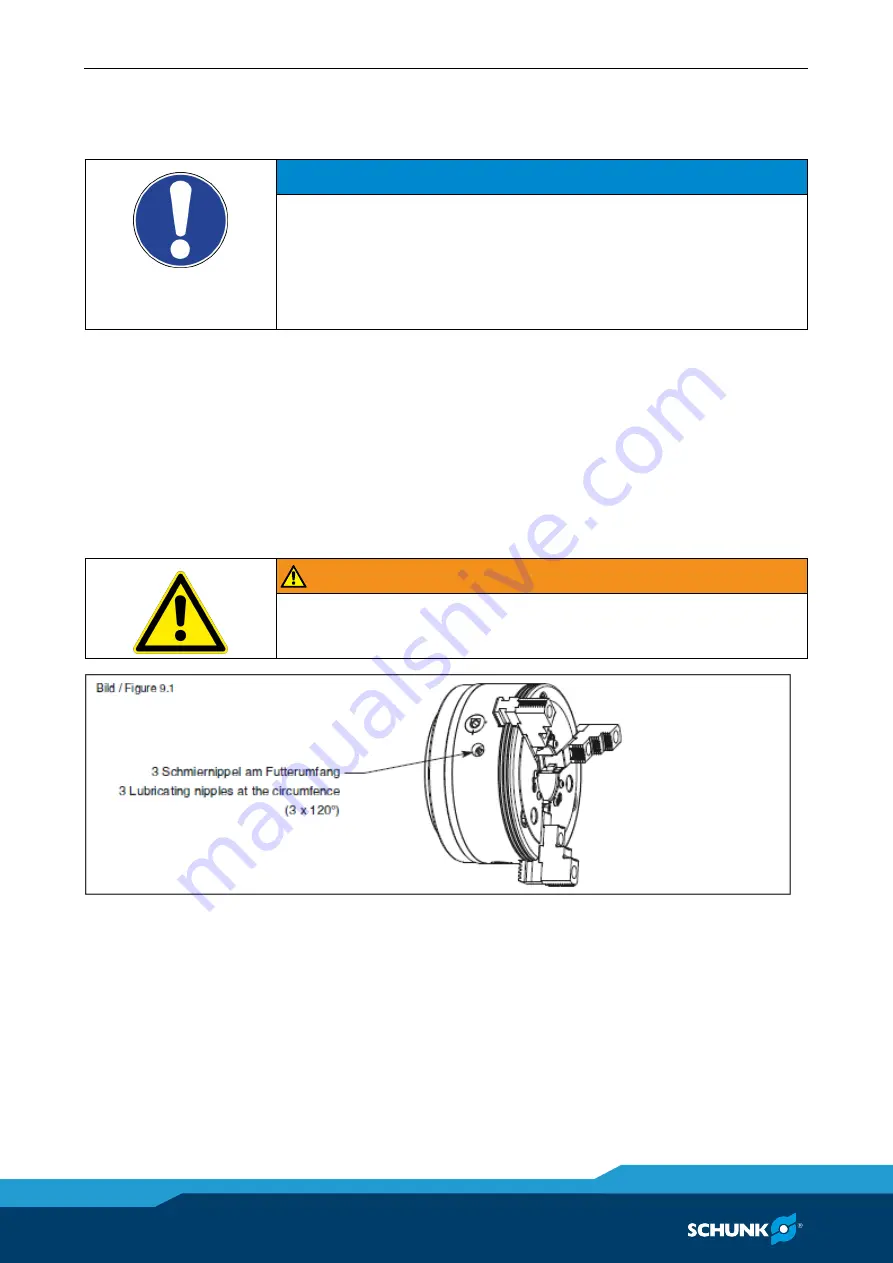

• Move the lathe chuck into the open position. Lubricate the

chuck at the three lubrication nipples (Fig. 9.1 Arrow) using a

high-pressure grease gun with six strokes of SCHUNK LINOMAX

special grease at each nipple.

• For optimum grease distribution, the clamping piston must

travel the entire clamping stroke several times after lubrication.

• Check clamping force, repeat procedure, if necessary.

11.2

11.3

Summary of Contents for ROTA THWvario

Page 60: ...Assembly drawing 60 01 00 ROTA THW vario en US Assembly drawing ROTA THW vario 215 62 13 13 1 ...

Page 61: ...Assembly drawing 01 00 ROTA THW vario en US 61 ...

Page 62: ...Assembly drawing 62 01 00 ROTA THW vario en US Segmented mandrel ROTA THW vario D 13 1 1 ...

Page 63: ...Assembly drawing 01 00 ROTA THW vario en US 63 Collet chuck ROTA THW vario F 13 1 2 ...