Technical data

24

02.00|ROTA TP |en

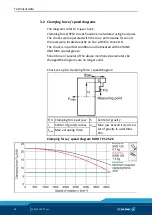

Calculation example: required initial clamping force for a given speed

Required initial clamping force F

sp0

for a given speed n

The following data is known for the machining job:

• Gripping from the outside in (application-specific)

• Machining force F

spz

= 3000 N (application-specific)

• max. speed of rotation n

max

= 3200

rpm

("Chuck data" table)

• RPM n = 1200 rpm (application-specific)

• Mass of one (!) top jaw m

AB

= 5.33 kg (applicationspecific)

• Center of gravity radius of top jaw r

sAB

= 0.107 m (application-

specific)

• Safety factor S

z

= 1.5 (according to VDI 3106)

• Safety factor S

sp

= 1.5 (according to VDI 3106)

Note:

Masses of the jaw mounting screws and T-nuts are not taken

into account.

First the required effective clamping force F

sp

is calculated using

the machining force stated:

Initial clamping force during shutdown:

Calculation of total centrifugal force:

For two-part chuck jaws, the following applies:

Centrifugal torque of base jaw and top jaw specified in "Chuck data"

table:

For the centrifugal torque of the top jaw, the following applies:

Centrifugal torque for one jaw:

The chuck has 3 jaws, the total centrifugal torque is:

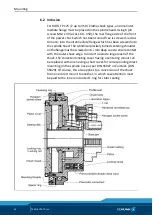

3.3.2