Function

02.00|ROTA TP |en

29

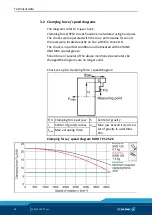

NOTICE

During actuation of the clamping device (clamping or releasing)

it must be ensured that a short ventilation time is maintained

between the switching processes. This ventilation time must last

at least 0.5 seconds, depending on the hose length. For this pur-

pose we recommend the use of a 4/3- or 5/3- way valve (central

position depressurized).

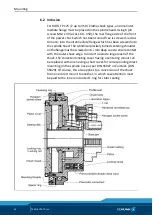

Pilot controlled check valve

The pilot-controlled check valve is an intrinsically sealed unit, and

comprises a valve body plus two locking pistons. Light mainte-

nance can be performed on it from the face side of the chuck via a

locking screw. The locking pistons of the valve unit control the rate

of the air that flows to and from the profile seals through two air

ducts. By changing the pressure of the air at the profile seals, the

air duct is vented into a cylinder chamber (relief chamber) on one

side. During this process, the compressed air is rerouted from one

cylinder chamber due to the valve housing moving axially while the

two individual locking/check pistons execute only one stroke when

locking their respective cylinder chambers. As a result of this process,

both O.D. and I.D. clamping are possible throughout the valve system.

4.4