Commissioning and maintenance

02.00|ROTA TP |en

43

Commissioning and maintenance

Initial operation

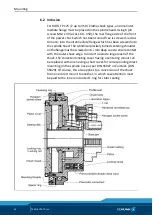

Check that the jaw guides and the piston of the ROTA TP-type

power chuck are sufficiently lubricated at the lubrication nipples

set into the base jaws; if not, relubricate the base jaws in the re-

tracted position with LINOMAX acid-free grease. When the chuck

is dried out, the clamping force is significantly reduced.

A locking screw with a hexagon socket is located on the front face

side of the chuck. Behind the locking screw, the pilot controlled

non-return valve controls the charging and exhausting of the two

pressure chambers and blocks the pressure toward the outside. It

is very important that the bore hole of the valve system is lightly

lubricated with oil so that the valve system can move easily. Too

much grease lubrication and dirt in the valve bore hole significantly

impair the function of the chuck and should be avoided.

NOTICE

When actuating the clamping device (clamping or releasing),

allow a short pause for ventilation between each shifting operation.

This ventilation pause must be at least 0.5 seconds, depending

on the length of the hose. We recommend using a 4/3 or 5/3

directional control valve for this (center position depressurized).

Note

Facing or skimming of the front-end power chuck is not permitted.

Drilling of the chuck on the front face side may be performed only

in accordance with the drilling patterns on the SCHUNK dimension

sheets.

7

7.1