Maintenance

40

03.00 | SRH-plus-D | Assembly and Operating Manual | en | 1424337

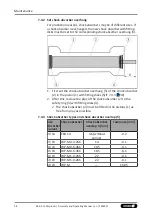

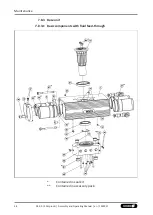

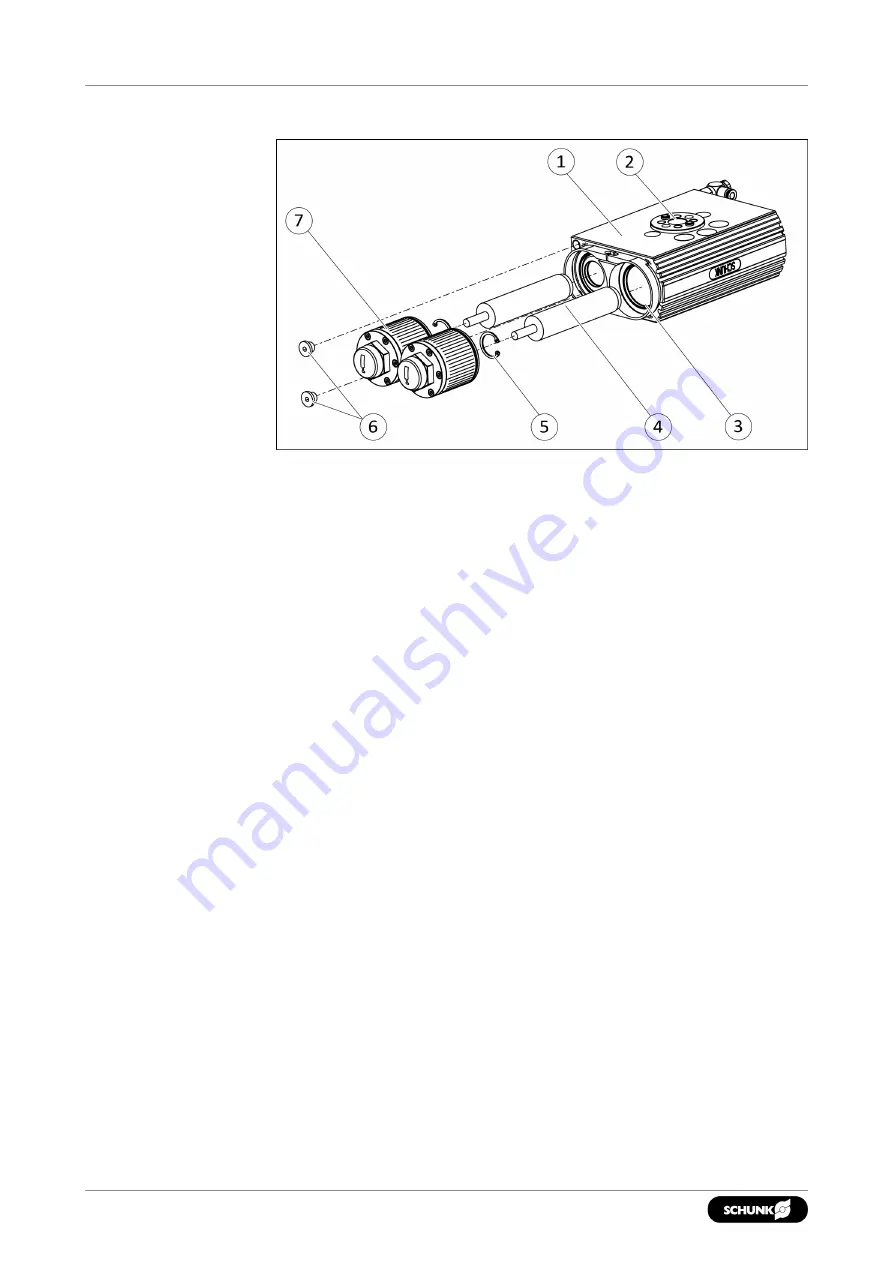

7.6 Changing shock absorbers (base unit)

1. Ventilate rotary actuator.

2. Unscrew screws (6).

3. Turn pinion (2) to end position.

4. Remove stop cover (7).

5. Remove safety ring (5) on piston (3).

6. Pull out shock absorber (4) with fitting disks.

7. Insert new shock absorbers.

8. Set shock absorber overhang (h),

9. Set safety ring (5) in the groove of the piston.

10. Turn pinion (2) to end position.

✓

Piston (3) is retracted into the housing (1).

11. Screw on stop cover (7) again.

12. Proceed analogously for the second shock absorber.

13. If necessary, adjust the shock absorber,

.