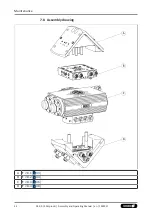

Maintenance

Interval [Mio. cycles]

for

SRH-plus-D 50 - 60

Maintenance work

1

Clean all parts thoroughly, check for damage

and wear, if necessary replace seals and

wearing parts,

.

1

Treat all grease areas with lubricant,

1

Check that the shock absorbers are working,

if necessary replace shock absorber

7.3 Lubricants/Lubrication points (basic lubrication)

WARNING

Risk of injury due to contact with lubricants!

Lubricant may cause irritation and allergic reactions if it contacts

the skin or eyes.

•

Avoid contact between lubricant and skin or eyes.

•

Wear safety goggles and protective gloves.

•

Observe information on the safety data sheet of the lubricant.

SCHUNK recommends the lubricants listed.

During maintenance, treat all greased areas with lubricant. Thinly

apply lubricant with a lint-free cloth.

Lubricant point

Lubricant

The teeth and the pinion

Toothgood 1

All seals

Sealgood 1

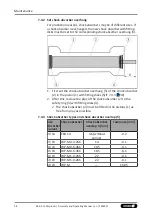

7.4 Inspect and set shock absorbers

7.4.1 Inspect shock absorbers

The shock absorbers are specially tested and can only be acquired

from SCHUNK. The shock absorbers have a limited lifespan,

depending on the load.

•

Regulary check that the shock absorbers are working.

✓

The shock absorber is working correctly if the product

moves softly into the end positions when set correctly and

the prescribed swiveling time is reached.

37

03.00 | SRH-plus-D | Assembly and Operating Manual | en | 1424337