Product description

02.00 | SWS-L | Assembly and operating manual | en | 0389037

13

4 Product description

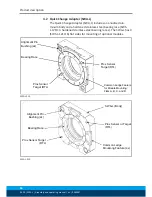

4.1 Quick-change head (SWK-L)

The Quick-change head (SWK-L) includes an anodized aluminum

body, a hardened stainless-steel locking mechanism, and hardened

steel alignment pins (see Figure).

The SWK-L plate has 4 (SWK-L-1210 Series: 6) flat sides for mount-

ing of optional modules. Flat ‘A’ is dedicated for mounting of the

control/signal module along with SWK-L supply air that is provided

through an air or valve adapter. Flats ‘B’, ‘C’, and ‘D’ (SWS-L-1210

Series and ‘F’) are fully interchangeable and optional modules can

be arranged to suit the application or robot dress as required.

The locking mechanism consists of a cylindrical housing with holes

that retain hardened chrome-steel balls. Tapered pins located on

the SWK-L mate with holes in the SWA-L to ensure repeatable

alignment during the coupling process. An extreme pressure

grease is applied to the cam, male coupling, ball bearings and

alignment pins to enhance performance and maximize life of the

components.

SWK-L-210:

A dual-sensor assembly is mounted into the body of

the SWK-L to verify the lock/unlock position of the piston and cam.

The sensors provide the lock and unlock (L/U) signals through the

control/signal module.

SWK-L-310 and 510:

Proximity sensors are designed into the body

of the SWK-L to verify the lock/unlock position of the piston and

cam. The sensors provide the lock and unlock (L/U) signals through

the control/signal module.

SWK-L-1210:

The SWK-L is comprised of 3 locking mechanisms.

Each locking mechanism consists of a cam, male coupling, and

chrome-steel balls. Tapered pins located on the SWK-L mate with

holes in the SWA-L to ensure repeatable alignment during the

coupling process. Extreme pressure grease is applied to the cams,

male couplings, ball bearings, and pins to enhance performance

and maximize the life of the SWK-L.

Proximity sensors (6 total) are designed into the body of the SWK-L

to verify the locked/unlocked position of each locking mechanism.

Due to the multiple locking mechanism design, the proximity

sensors are grouped such that 3 sensors are for Lock and 3 are for

Unlock. The Lock/Unlock signal at each locking mechanism is

routed to the signal junction module. The junction module

provides the control/signal module with the Lock/Unlock state of

the SWK-L. See the cable routing illustrations in chapter "Installa-

tion" to understand the relationship between the sensors, junction

module and control module.)