Installation

24

02.00 | SWS-L | Assembly and operating manual | en | 0389037

Lock-up should occur with the SWK-L in the No-Touch™ locking

zone (see following table), but not touching the SWK-L. As locking

occurs, theSWK-L should draw the SWA-L into the locked position.

Tool Stands may also need to incorporate means for covering tools

and electrical modules to protect them in dirty environments, such

as grinding or welding. Alternatively, locating Tool Stands in areas

shielded from weld spatter, fluids, adhesives, or other debris

would eliminate the need for tool covers.

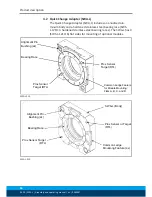

SWK-L

SWA-L

Twisting

Cocking Offset

(About X and Y)

X, Y and Z Offset

Offset Definitions

Maximum Recommended Offsets Prior to Coupling

Model

No-Touch™ Zone Z

Offset (Max)* (mm)

X and Y Offset (Max)**

(mm)

Cocking Offset (Max)

(degrees)

SWS-L-210

2.5

±2

±1

SWS-L-310

2.5

±2

±1

SWS-L-510

2.5

±2

±1

SWS-L-1210

1

±2

±1

* Maximum values shown. Decreasing actual values will minimize wear during coupling/

uncoupling.

** Actual allowable values may be higher in some cases but higher offsets will increase

wear during coupling.