Troubleshooting

02.00 | SWS-L | Assembly and operating manual | en | 0389037

31

7 Troubleshooting

Check these conditions for all symptoms prior to troubleshooting:

• Proper pneumatic and electrical connections have been made

to the SWS-L.

• Air is supplied at a minimum of 5 and a maximum of 6,9 bar.

• No air or vacuum can be trapped in a de-energized Lock or Un-

lock port (pressure must be vented to atmosphere).

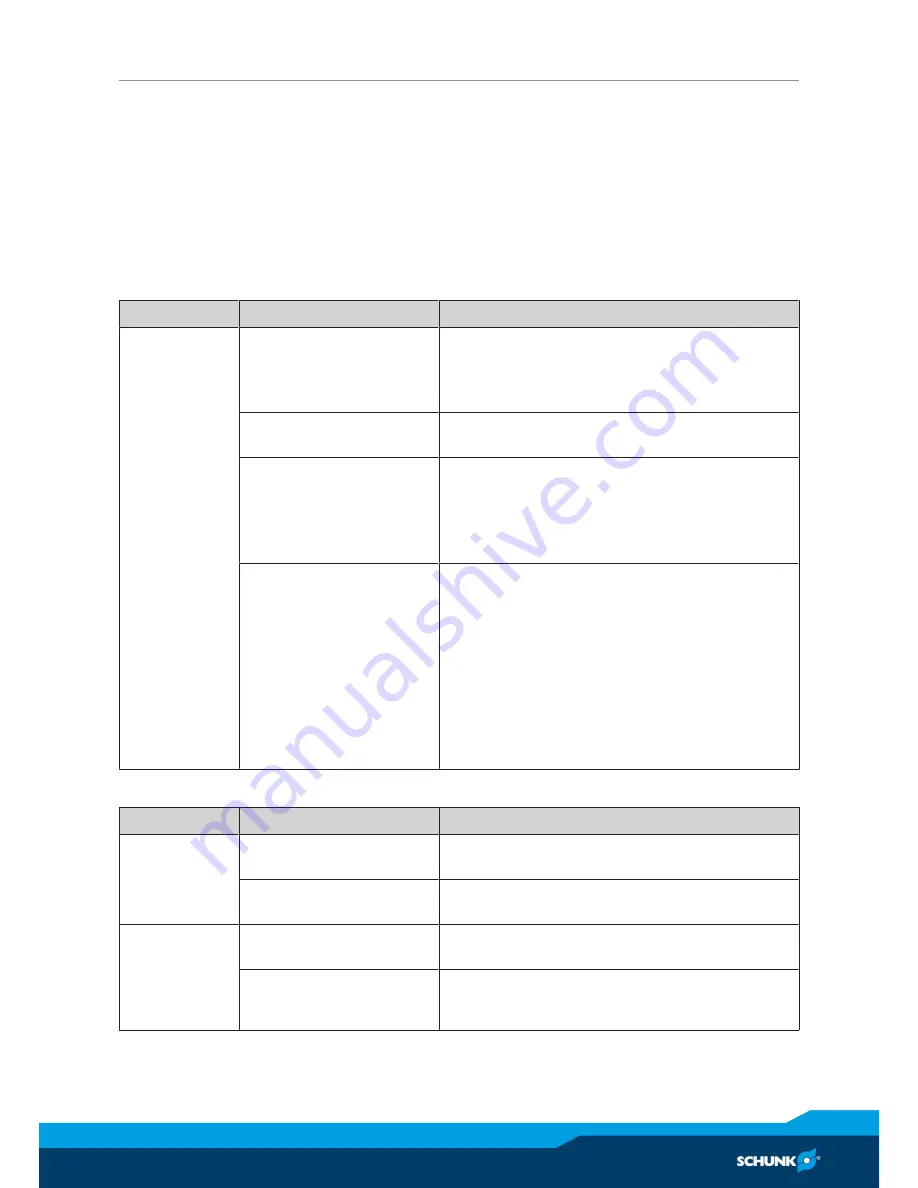

SWS-L-210, 310, 510

Symptom

Cause

Resolution

Unit will not

lock or unlock

The ball bearings and/or

cam are not moving

freely in the male coup-

ling.

Clean and lubricate as needed to restore

smooth operation Maintenance.

The control module is not

operating correctly.

Check the troubleshooting section of the

manual for the specific module.

The SWK-L and SWA-L are

not within the specified

No-Touch zone when at-

tempting to lock.

Check that the Tool is properly seated in the

Tool Stand.

Re-teach the robot to bring the SWK-L and

SWA-L closer together prior to attempting to

lock.

Ready-To-Lock (RTL)

sensors not activated in-

dicating Tool is not posi-

tioned properly

Check that the SWA-L is properly seated in the

tool stand.

Re-teach the robot to bring the SWK-L and

SWA-L closer together prior to attempting to

lock.

Check that both RTL sensors are not damaged.

Replace damaged RTL sensors as necessary.

Check all cables for damage and that they are

connected properly to the signal control mod-

ule. Replace damaged cables as necessary.

SWS-L-310 and 510

Symptom

Cause

Resolution

Unit is locked

but Lock signal

does not read

“on” (true).

Lock sensor is damaged.

Replace Lock sensor or Sensor Assembly as ne-

cessary Maintenance.

Lock sensor is out of posi-

tion.

Replace the Lock sensor or Sensor Assembly as

necessary.

Unit is un-

locked but Un-

lock signal

does not read

“on” (true).

Unlock sensor is damaged Replace Unlock sensor Or Sensor Assembly as

necessary Maintenance.

Unlock sensor is out of

position

Replace Unlock sensor or Sensor Assembly as

necessary.