Maintenance and Care

36

02.00 | SWS-L | Assembly and operating manual | en | 0389037

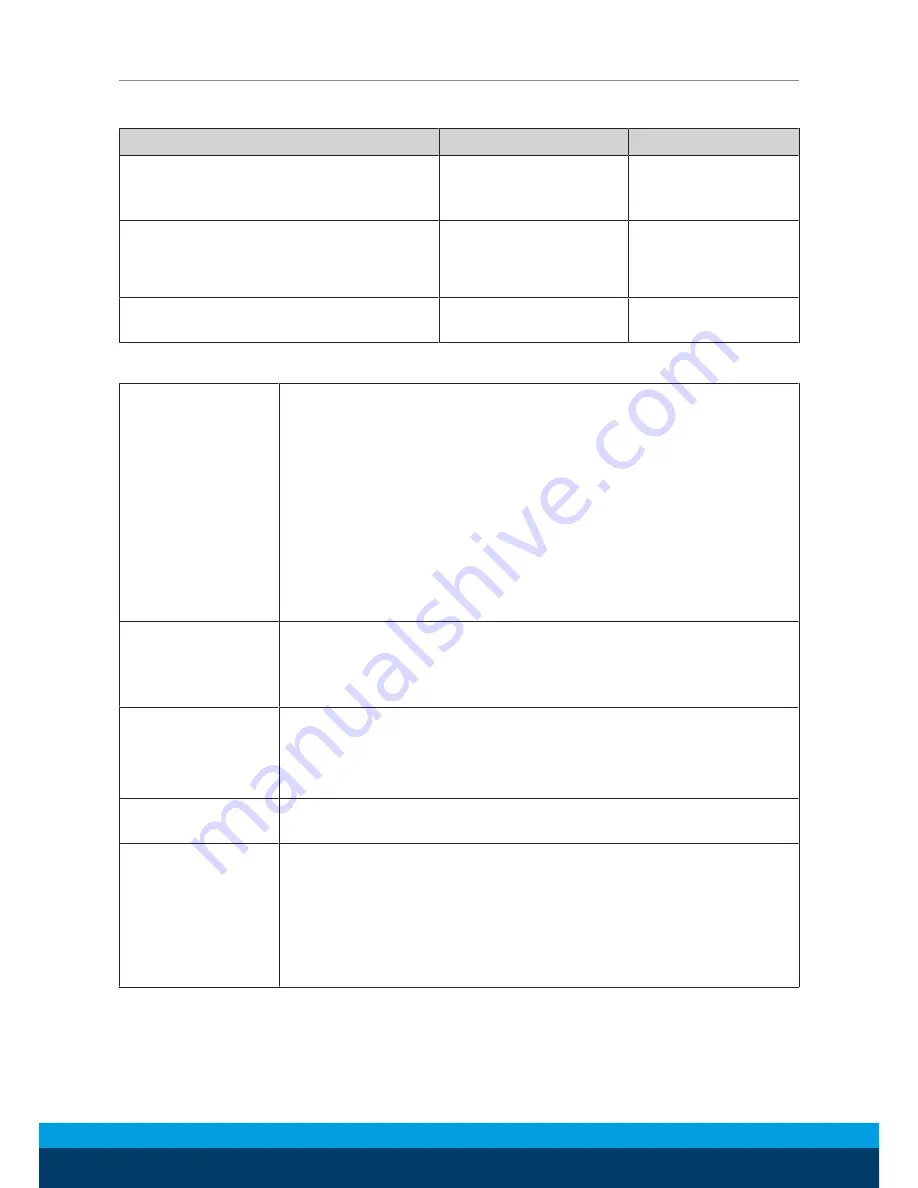

Schedule

Application(s)

Tool Change Frequency Inspection Schedule

General Usage

Material Handling

Docking Station

> 1 per minute

Weekly

General Usage

Material Handling

Docking Station

< 1 per minute

Monthly

Welding/Servo/Deburring

Foundry Operations (Dirty Environments)

All

Weekly

Checklist

Balls/Alignment

Pins/Holes/Bearing

Race

Inspect for lubrication and wear. A NLGI #2, lithium-based grease

with molybdenum disulfide additive is suggested for locking mechan-

ism and alignment pin lubrication. Over time, lubricants can become

contaminated with process debris. Therefore, it is recommended to

thoroughly clean the existing grease and replace with new as

needed. Link Schmierstoffe/Schmierstellen.

Excessive alignment pin/bushing wear may be an indication of poor

robot position during pickup/drop-off. Adjust robot position as

needed. Check Tool Stand for wear and alignment problems.

Wear on the balls/bearing race could be an indication of excessive

loading.

Mounting Hard-

ware /

/Interface Connec-

tions

Inspect for proper torque and interference or wear, abrasions, cuts

of hoses, and electrical cables. Tighten and correct as required.

Seals

Inspect for wear, abrasion, and cuts.

Exposed O-rings and rubber bushings may be subject to damage dur-

ing normal operation. Replace damaged o-rings and rubber bushings

as needed.

Sensors and Cables

Inspect sensor cables and connectors for any damage, cuts, and ab-

rasion.

Electrical Contacts/

Pin Block (Modules)

Inspect for wear and abrasion.

Exposed contacts may be subject to damage during normal opera-

tion.

Clear debris from the area of the contacts using compressed air.

Do not directly clean contacts as abrasion may occur and the per-

formance of the contact may be compromised.