24

02.00 | KSF3, KSF3-LH, KSF3-F | Assembly and Operating Manual | en |

1467140

Assembly and connection

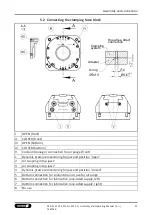

Use for cleaning the clamping surfaces

The customer can create channels in the top jaw in order to clean

the clamping and bearing surfaces by means of compressed air.

In doing so, the transfer dimensions ØC, D, E and F must be

observed.

Dynamic pressure monitoring of the workpiece flat work surface

For this purpose, the customer must provide the top jaw with a Ø2

mm monitoring hole on the workpiece flat work surface. This

ensures that the escaping air purge can be released up to where

contact is made with the mounted workpiece and that a

differential pressure measurement can be carried out via a

differential pressure switch.

In doing so, the transfer dimensions ØC, D, E and F must be

observed.

Max. pressure 2 bar.

Limit volumetric flow to 10 l/min

Summary of Contents for TANDEM KSF3 100

Page 46: ...SCHUNK ...

Page 47: ...SCHUNK ...