02.00 | KSF3, KSF3-LH, KSF3-F | Assembly and Operating Manual | en |

1467140

39

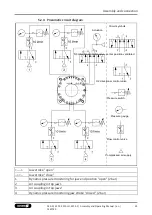

Sealing kits, accessory kits and parts lists

86

Screw

8

●

●

87

O-ring DIN ISO 3601

10

●

■

☐

●

89

Set-screw

2

●

●

93

Set-screw

2

●

●

100

T-handle

2

●

●

Parts list key

a = for all sizes

y = wearing part

b = for size 100

■

= included in the piston chamber sealing

kit

c = for size 160

☐

= included in the monitoring sealing kit

d = for size 250

z = included in accessory kit

* Individual components are specially tuned to one another and

cannot be replaced by the customer.

Summary of Contents for TANDEM KSF3 100

Page 46: ...SCHUNK ...

Page 47: ...SCHUNK ...