Maintenance and care

02.00 | KSF3, KSF3-LH, KSF3-F | Assembly and Operating Manual | en |

1467140

33

•

After completion of the assembly, carry out a leak test and a

function test.

}

7.4.4 [

/

000]

•

Variant "PM": Pay attention to the correct alignment of the

monitoring pieces! When mounting the base jaws, make sure

that the O-ring (44) is not sheared off. Readjust the pneumatic

jaw end position control before mounting the guide strips (6)

(see next chapter).

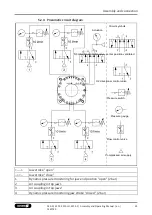

7.4.3

Adjustment of the pneumatic jaw end position monitoring (PM)

Jaw 1: monitoring open jaw position

•

Move base jaws to OPEN position.

•

Screw the set-screw (61) into the bore hole o up to the stop and

then unscrew it again by a few turns.

•

Slowly screw the set-screw (61) into the bore hole oo until the

differential pressure sensor emits a switching signal.

•

Hand-tighten set-screw (61) in bore hole o.

•

Screw set-screw (63) in both bore holes and hand-tighten.

Jaw 2: monitoring closed jaw position

•

Move base jaws to CLOSED position.

•

Screw the set-screw (61) into the bore hole oo up to the stop

and then unscrew it again by a few turns.

•

Slowly screw the set-screw (61) into the bore hole o until the

differential pressure sensor emits a switching signal.

•

Hand-tighten set-screw (61) in bore hole oo.

•

Screw set-screw (63) in both bore holes and hand-tighten.

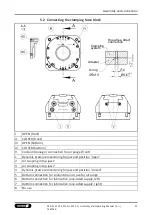

7.4.4

Leak test

The following components are required to check for leaks:

pressure gauge, shut-off valve, supply line and quick coupling.

•

Check for leaks in the clamping system in the OPEN and CLOSED

positions.

Summary of Contents for TANDEM KSF3 100

Page 46: ...SCHUNK ...

Page 47: ...SCHUNK ...