02.00 | KSH3 IM | Assembly and Operating Manual | en | 1477686

23

Assembly and connection

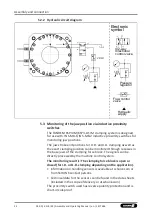

For the proper use of the proximity switches, observe the

following:

•

Do not pull forcefully on the sensor cable.

•

Do not subject the sensor cable to tensile strain.

•

Install the sensor connection cable straight and do not twist it.

•

Tighten the counter nut for clamping the sensor using a suitable

tool and moderate manual force.

•

Do not exceed the permissible bending radius of the cable (

☞

catalog specifications)

•

Position the sensor so that the signal LED on the sensor head is

clearly visible (with cover, LED is not visible).

•

Prevent the proximity switch from coming into contact with

hard objects or with chemicals; in particular, nitric, chromic or

sulfuric acid.

Proximity switches are electronic components which can react

sensitively to high-frequency interference or electromagnetic

fields.

•

Check that the cable is correctly connected and installed. There

must be sufficient distance between the switches and sources

of interference and their supply cables.

•

Parallel switching of multiple sensor outputs of the same design

(npn, pnp) is permissible, though this does not increase the

permissible load current.

•

Please note that the leakage current of the individual sensors is

accumulative (by about 2 mA).

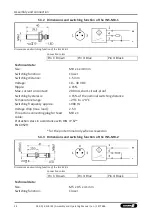

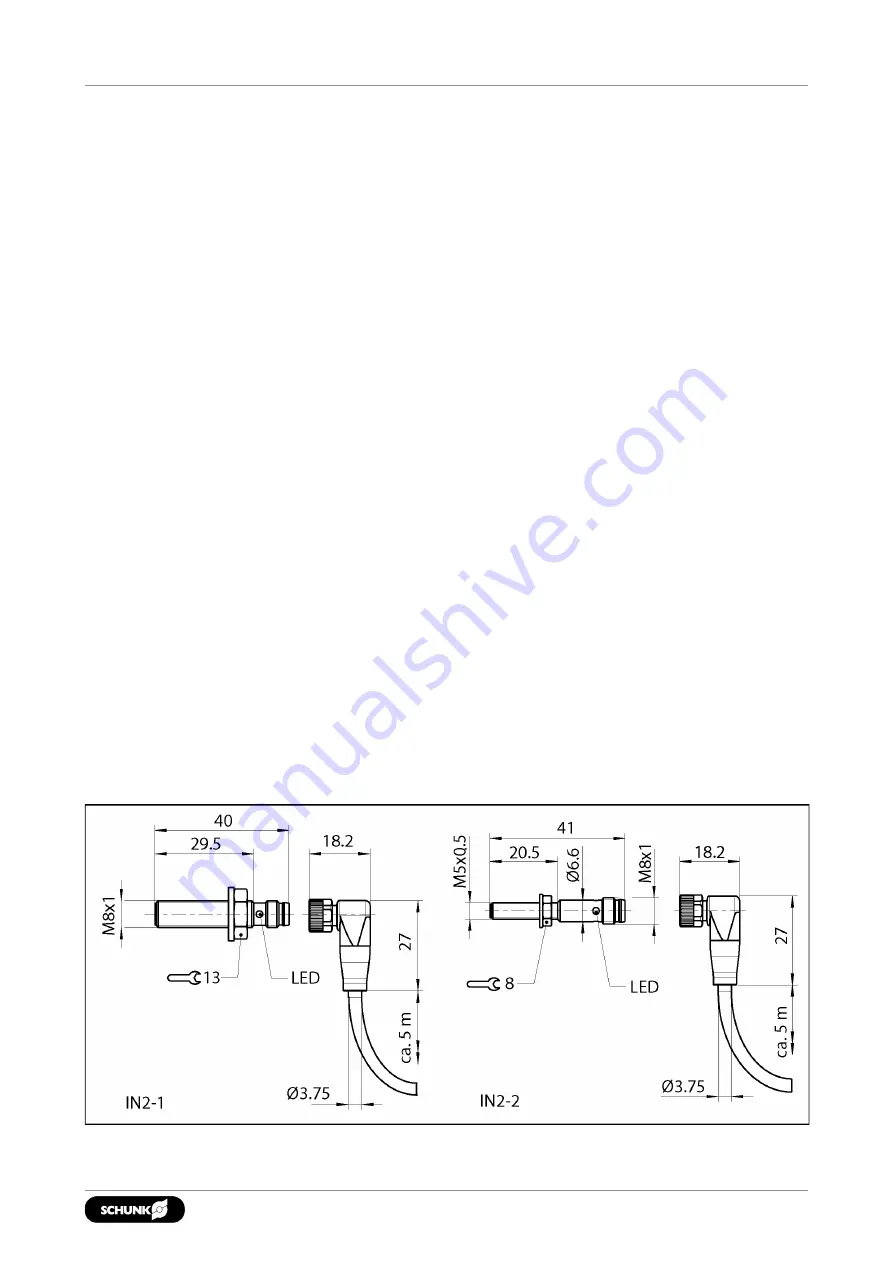

5.3.1

Basic construction and dimensions of the inductive proximity

switches with scew-fastened connection cable

IN S-M8-1 left and IN S-M8-2 right