02.00 | KSH3 IM | Assembly and Operating Manual | en | 1477686

29

Assembly and connection

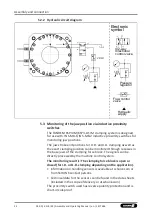

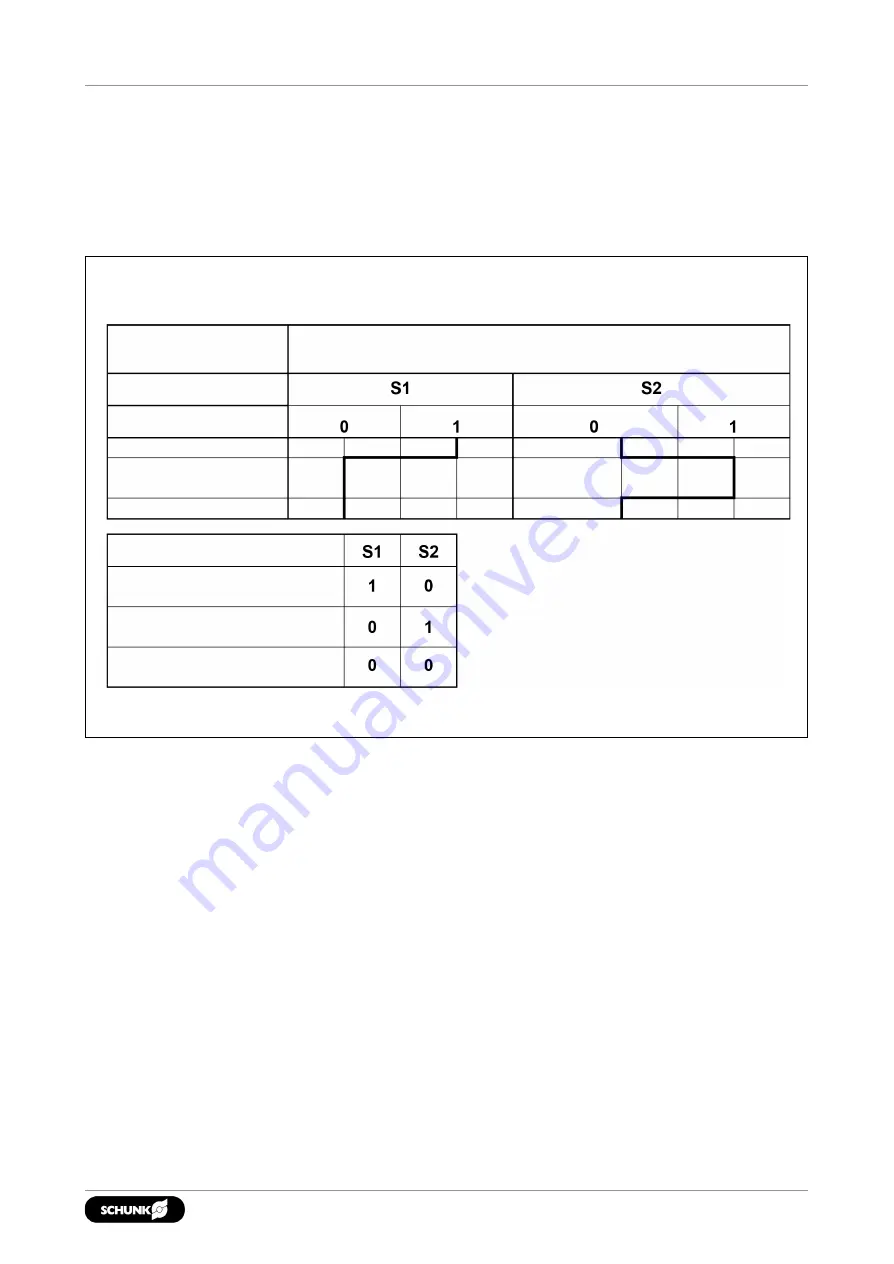

The circuit diagram and the functional diagram show the

recommended settings of the proximity switches for monitoring

"End position closed" and "Clamping position reached."

The circuit diagram can also be adjusted for monitoring "Stroke

end position open" and "Missed clamping position." The proximity

switches can also be individually adjusted on the retaining plate.

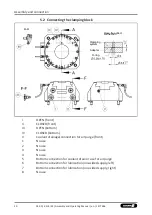

Fig.°7 Circuit diagram for internal workpiece clamping

clamping force block closed

Jaw end position closed

Clamping position

force block open

Jaw end position on clamping

proximity switch

Signal output

Jaw end position open

Clamping position

Jaw end position closed

Circuit diagram proximity switch

Circuit diagram and monitoring/control functions for internal workpiece clamping