02.00 | KSH3 IM | Assembly and Operating Manual | en | 1477686

35

Maintenance and care

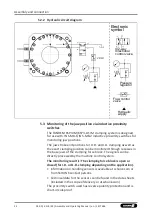

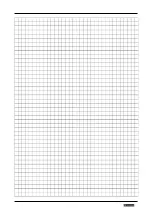

•

To use central lubrication, the set-screwsof

the factory sealed connections (6, 7) must

be removed.

•

For proper lubrication, both supplylines

must be connected.

•

The central lubrication system must be

suitable for greases of NLGI 2 classification.

•

Only lubricate in the open position.

•

After greasing, run through the complete

stroke several times.

•

Greasetobeusedandlubrication

Size

Grease quantity (per connection) [cm

3

]

64

2

100

4

140

4

160

4

250

4

7.4.2

Basic cleaning

For basic cleaning, the product must be disassembled, cleaned and

reassembled.

Disassembly Before disassembling the product, switch off the machine and

secure it against being switched on again. Then remove all

compressed air lines. No residual energy may be left in the product.

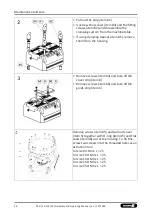

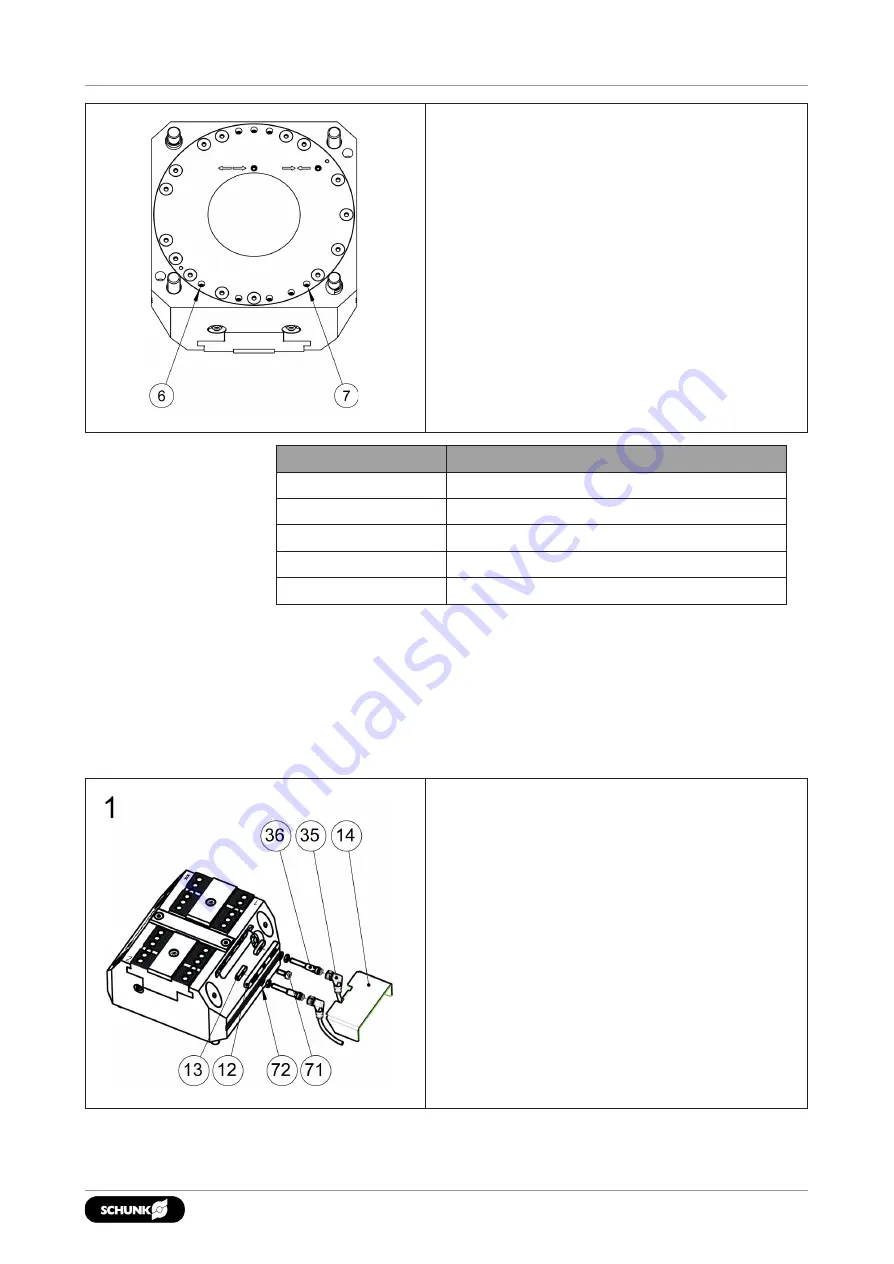

•

Disassemble the supply cable to the pin

terminal of the inductive proximity switches

on the separable elbow fitting

•

Remove the screw (item 71) and take the

retaining plate (item 12) together with the

cover (item 14) and the proximity switches

(item 36) out of the body

•

Each proximity switch is fastened with a

hexagon nut and washer (item 72)

•

The counter-supports (item 13) can be

disassembled simultaneously