38

02.00 | KSH3 IM | Assembly and Operating Manual | en | 1477686

Maintenance and care

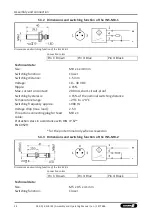

7.4.3

Testing the leakage and tightness of the hydraulic system

The following is needed to check for leaks:

hydraulic unit or manually actuated hydraulic pump, pressure

gauge, shut-off valve and quick couplers.

•

Check for tightness in the clamping system in the OPEN and

CLOSED positions

Connect the components for the leakage and tightness test on

the clamping system in the following order:

1.

Adjust the hydraulic unit with pressure gauge and shut-off valve

to minimum pressure.

2.

Connect the hydraulic screw fittings to the frontal OPEN and

CLOSED connections.

3.

Link the supply line and hydraulic coupling to the hydraulic

screw fittings.

The leakage and tightness test is to be performed in the following

order:

1.

Actuate the clamping force block with reduced hydraulic

pressure. Check the clamping force block for free movement by

opening and closing the jaws several times.

2.

Check the clamping force block with the maximum permissible

hydraulic pressure.

3.

Inspect the outside of the TANDEM clamping force block for

visible signs of damage and oil leakage.

Measures in the event of a leaking hydraulic system

If the clamping system is leaking, check the fittings first.

Seal any leaking fittings. Once the fittings are sealed, check for

leaks in the clamping force block and replace if necessary (see the

chapter "Disassembling and assembling the clamping

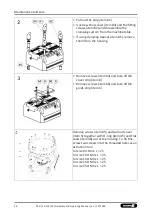

7.4.4

Assembly devices piston seals

To assemble the seal (item 40), a multi-part assembly tool is

required. If no assembly tool is available, repair work on the

TANDEM clamping force block should be carried out by SCHUNK.

1.

Assembly

•

Disassemble the two-part seal (item 40) and grease with Renolit

HLT 2 or an equivalent grease.

•

Pull the O-ring of the seal (item 40) over the cylinder piston

(item 4) and into the groove. (Do not stretch or tear the O-ring.)

•

Stretch the sealing ring with an expansion sleeve over the cone

sleeve and slide over the cylinder piston and the O-ring that was

previously inserted into the groove.