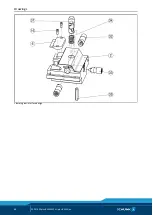

Seal Kit and Parts List

02.00|KSPplus-BWM KSP-LHplus-BWM |en

43

4

Cylinder piston

1

5

Cover

1

6

Covering strip

2

7

Covering strip

1

8***

Plug

4

9***

Fitting screw, 12f7/M10

2

10

Lubrication nipple

4

11

Locking screw

2

12**

Quad ring, 126.59 x 3.53

1

13

Sound absorber

1

14

Screw, DEI 4762/10.9 M10x25 mm

1

15**

Combined sealing ring

1

16

Countersink screw, DIN EN ISO 4026 M3x6 mm

4

17**

O-ring, DIN 3771 150 x 2.00

1

18***

O-ring, DIN 3771 12 x 2.00

4

19***

Screw, DEI 4762/10.9 M10x40 mm

4

20**

O-ring, DIN 3771 5.5 x 1.00

17

21

Countersink screw, DIN EN ISO 10642/10.9 M5x20 mm

15

22**

O-ring, DIN 3771 4.5 x 1.00

2

23

Set-screw, similar to DIN EN ISO 4026/45H M5x4 mm

4

25

Countersink screw, DIN EN ISO 10642/10.9 M5x10 mm

2

26

Set-screw, DIN EN ISO 4026/45H M4x4 mm IN6RD/VZ/PA 1

27***

Clamping sleeve, DIN EN ISO 13337 13 x 18

2

31

Lock bolt

2

32

Unlocking bolt

4

33

Unlocking bolt 2

2

34

Compression spring

2

35

Cylindrical pin, DEI 7979 - 5 M6x24 mm

1

KSH-LHplus 160-BWM

Item

Designation

Quantity

1*

Body

1

2*

Base jaw

2

3*

Chuck body

1

4

Cylinder piston

1

5

Cover

1

6

Covering strip

2

7

Covering strip

1

8***

Plug

4

9***

Fitting screw, 12f7/M10

2