Maintenance and care

34

02.00|KSPplus-BWM KSP-LHplus-BWM |en

Maintenance and care

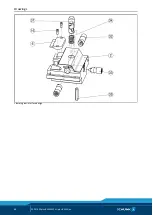

The item numbers specified for the corresponding individual

components relate to chapter drawings.

The item numbers to the corresponding individual parts refer to

the drawing in chapter 11.

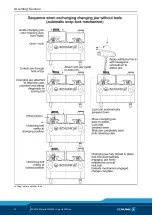

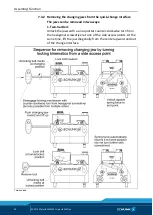

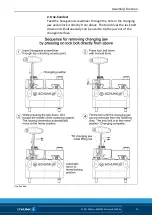

Regularly check to see if the motion kinematics of the jaw locking

mechanism are working properly. Make sure the turning mechan-

ics are easy to move and automatically reset. The conical lock bolt

must smoothly and completely rise up.

The base jaws (2), chuck piston (3) and housing (1) are made to go

together. To replace these parts, ship the entire clamping system

to SCHUNK along with a repair order.

In order to keep the clamping block in proper working order,

observe the following notes:

• Make sure that the bore for the coolant drainage is always kept

clear!

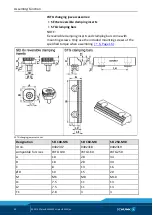

• Depending on the load but at least once a month or every 10,000

clampings, lubricate the guides on the two frontal or the two lateral

lubricating nipples with LINOMAX 200 or equivalent lubricant.For

this purpose the chuck jaws should be in opened position. For this

purpose the chuck jaws should be in opened position.

• Replace the base jaws and chuck piston at least every three

months or more often, if necessary (see

).

Clean the housing, base jaws and chuck piston, and lubricate all

the guides (housing, base jaws, chuck piston) with LINOMAX

200. Reassemble everything and relubricate the two front or

two side lubricating nipples with LINOMAX 200.

(Product information about LINOMAX 200 can be requested by

SCHUNK).

CAUTION

Allergic reactions due to grease in contact with skin!

Wear gloves.

Disassembling and assembling the clamping block

NOTE:

The base jaws (2), chuck piston (3) and housing (1) are made to go

together. These parts cannot be replaced individually. To replace

these parts, ship the entire clamping block to SCHUNK along with a

repair order.

9

9.1