Assembly and Operating Manual

TENDO HSK-F 63

Hydraulic expansion toolholder

for wood and plastic machining

1 General

1.1 About this manual

This manual is part of the product and contains important

information for safe and correct use. It must be kept accessible

at all times. Personnel must have read and understood this

manual before starting any work. All safety notes and the

associated specifications in particular must be observed and

complied with. Illustrations may differ from the actual design.

1.2 Applicable documents

– General terms of business

– Catalog data sheet of the purchased product

The other applicable documents can be downloaded from

schunk.com

.

1.3 Warranty

The warranty is valid for 24 months from the date of delivery

from the production facility if the product is used as intended

and in compliance with the prescribed operating data.

Wear parts and parts that come in contact with the tool or

machine are not covered by the warranty.

1.4 Illustration of warnings

WARNING

Dangers for persons!

Non-observance can lead to irreversible injury and even

death.

CAUTION

Dangers for persons!

Non-observance can cause minor injuries.

NOTICE

Material damage!

Information about avoiding material damage.

1.5 Scope of delivery

– Product

– Assembly and Operating Manual

1.6 Accessories

The following accessories for the product are available

separately:

– Test shaft for monitoring the expansion rate

– Allen key for operating the clamping screw

– Hexagon socket wrench for length adjustment

– GZB-S intermediate sleeves for clamping several different

shank diameters

– GZB-S sleeve remover for removing intermediate sleeves

2 Basic safety notes

2.1 Appropriate use

– The product is used to clamp rotationally symmetric tools.

– The product is intended for industrial use on wood and

plastic processing machines.

– The product is intended for installation in a machine/

automated system. The applicable guidelines for the

machine/automated system must be observed and complied

with.

– The product may only be used and operated within the scope

of the technical data and the specifications in this

manual,

.

2.2 Inappropriate use

The product is not being used as intended if:

– The information in the technical data is not observed when

using and operating the product

.

– The maintenance and storage instructions are not

.

– The product is used with heat shrinking technology.

2.3 Ambient conditions and operating conditions

The ambient and operating conditions must correspond or be

adapted to the version of the product and the specifications in

the technical data.

2.4 Structural changes, spare parts

Structural changes such as modification and reworking, e.g.

additional threads, bore holes or attachments, may only be

carried out with the written approval of SCHUNK. Only use

original spare parts and spares authorized by SCHUNK.

2.5 Notes on safe operation

–

The product is designed for an operating/product

temperature of +50 to +70°C.

This temperature range offers

the optimum clamping force.

– The product must not be clamped without a tool above 25°C.

– Never combine multiple product extensions.

– Only use SCHUNK intermediate sleeves and always insert up

to the fixed backstop point. The use of intermediate sleeves

can reduce the transmittable torque.

– Long, projecting or heavy tools may only be clamped if the

speed of rotation is reduced according to the ambient and

operating conditions on site. The level of reduction is the

responsibility of the operator and must ensure safe operation

of the product.

– Maintain and service the product on a regular basis.

– Do not remove the air bleed screw (secured with pin or

resin).

– All repair work must be performed by SCHUNK.

– The operational safety and function of the product must not

be impaired by external influences.

– Follow the country-specific applicable safety, accident

prevention, and environmental protection regulations for the

application field of the product.

– Use mechanical screwdrivers only after approval by SCHUNK.

2.6 Personnel qualifications

– All operations may only be carried out by personnel that are

qualified and instructed for the respective operation.

– Personnel qualifications must comply with the on-site

country-specific requirements and laws.

2.7 Personal protective equipment

– When working on and with the product, follow the

respective country-specific legal requirements for

occupational health and safety, and wear the necessary

personal protective equipment.

– Follow country-specific accident prevention regulations and

the general safety notes.

2.8 Transport

To avoid product damage, the transport and handling of the

product must be adapted according to the version, weight and

packaging of the product. If necessary, use additional aids.

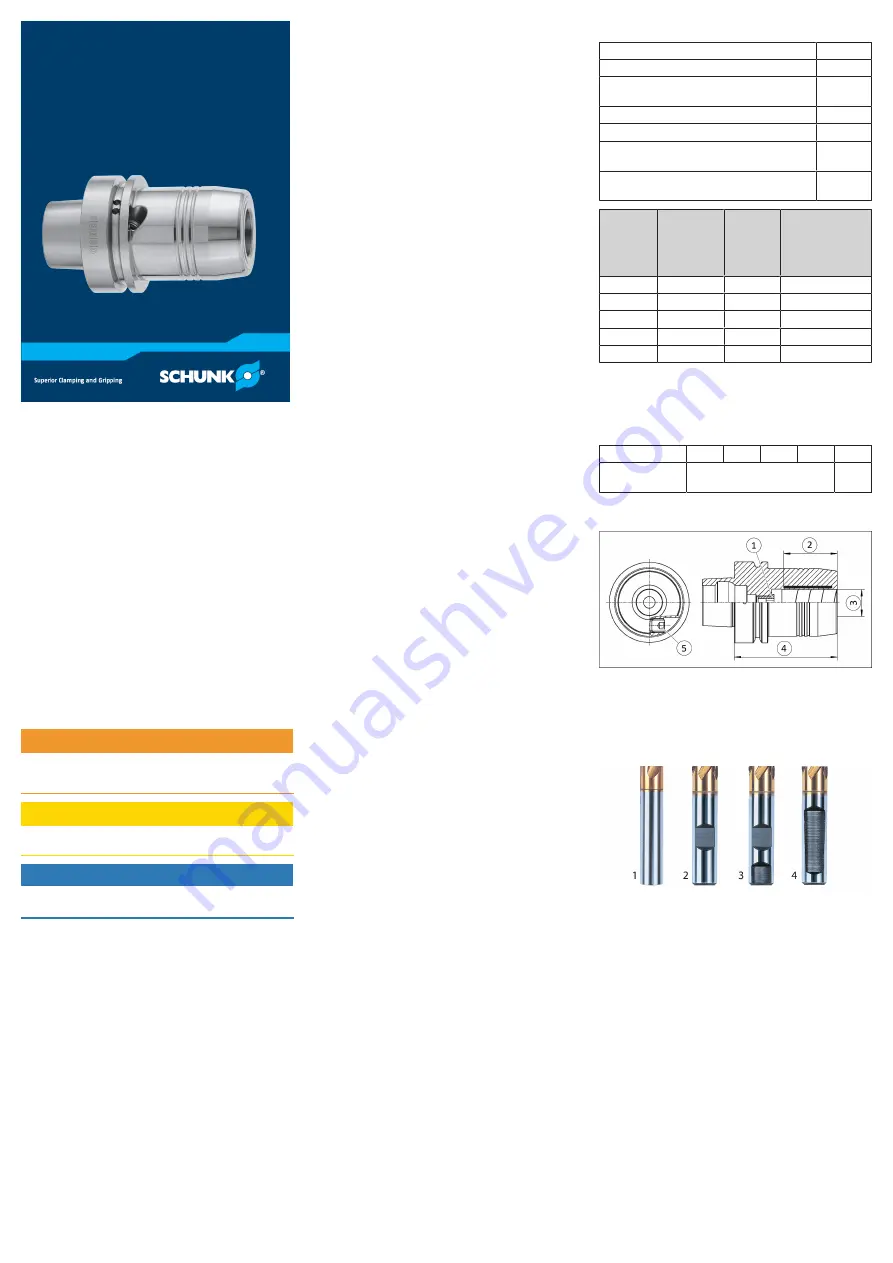

3 Technical data

Operating temperature range [°C]

50 – 70

Max. unclamping temperature [°C]

45

Test temperature for

the clamping force control [°C]

20 – 25

Max. coolant pressure [bar]

80

Tool shank tolerance

h6

Max. tightening torque of

the clamping screw [Nm]

10 – 12

Adjustment travel of

the length adjustment screw [mm]

10

Clamping Ø

[mm]

Permissible

transmittable

torque*

[Nm]

Minimum

clamping

depth

[mm]

Permissible radial

force F on the

product at 50 mm

projecting length

L1 [N]

10

20

31

540

12

25

36

650

16

60

39

1410

20

130

41

1860

25

170

47

4400

* Tool shank minimum tolerance h6, tool shank oiled.

Measured at room temperature, the transmittable torque

increases at higher operating temperatures.

The load limits of the spindle holder must be observed.

Max. speed of rotation** for clamping diameter

Clamping Ø [mm]

10

12

16

20

25

Max. speed of

rotation [RPM]

50000

25000

** depending on the interface of the spindle and tool to be

clamped.

① Length-setting screw***

④ Projecting length L1

② Minimum clamping depth ⑤ Clamping screw

③ Clamping diameter

*** if available.

3.1 Permitted shank types

1. Shank type according to DIN 1835-1 form A and DIN 6535

form HA

2. Shank type according to DIN 1835-1 form B and DIN 6535

form HB (up to Ø 20 mm)

3. Shank type according to DIN 1835-1 form B and DIN 6535

form HB (from Ø 25 mm)

4. Shank type according to DIN 1835-1 form E and DIN 6535

form HE

Tool shanks with reliefs (forms 2, 3 and 4) can impair the

balancing grade and concentricity of the overall system.