Basic safety notes

10

06.00 | NSA plus 120; NSA plus 160 | VERO-S quick-change pallet system | en |

0489070

Safety during assembly and maintenance

During assembly, connection, setting, commissioning and testing,

it is important to eliminate the possibility of the fitter or any other

persons accidentally activating the system.

Refrain from all work that could threaten safety.

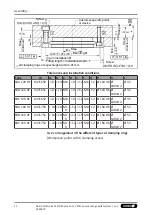

2.4.1 Holding force and screw strength

The holding force of the Quick Change Pallet System is essentially

limited by the strength of the screwed connections with which

the clamping ring is connected to the pallet or device. On this

basis fastening screws of the property class 12.9 are to be used

only.

Only original SCHUNK clamping rings may be used.

When the clamping ring is used in the customer’s own assembly

device, the customer is to provide for a sufficiently dimensioned

tap and satisfactory strength of the fastening material.

2.4.2 Constructional changes, attachments, or modifications

Additional threads, bore holes or attachments which are not

supplied as accessories by SCHUNK may affect safety. They may

only be applied after obtaining the prior consent of SCHUNK.

2.5 Personnel qualification

The assembly and disassembly, commissioning, operation and

maintenance of the system may be performed only by trained

specialist personnel.

Every person called upon by the operator to work on the system

must have read and understood the complete Assembly and

Operating Manual, especially chapter 2 "Basic safety notes".

Trainees may work on machines and technical equipment in which

a Quick Change Pallet System is installed provided that they are

supervised at all times by qualified specialist personnel.