Assembly

04.00|NSE plus, NSL plus, NSD plus |en

53

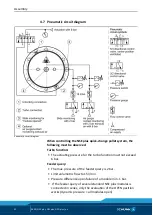

Air purge/contact monitoring (optional):

• Max. pressure 2 bar.

• Limit volumetric flow to 15 l/min.

Exhaust air (optional):

• Max. pressure 6 bar.

• The exhaust air must be switched off before the modules are

locked, as otherwise an air cushion may form.

In order to guarantee reliable evaluation, the pressure and air vol-

ume must be held constant. Pressure fluctuations can affect the

settings of the pressure switch and lead to incorrect measurement

results. The length and cross-section of the line can affect the

switching time of the control components. It may be necessary to

readjust the control components. Check the control components

of the monitoring functions at regular intervals. If errors occur in

the monitoring control system, you must detect the cause of the

error.

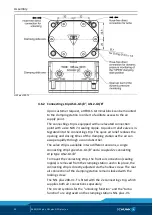

Screw tightening torques

Tightening torques for mounting clamping pins

(Screw quality 12.9)

Screw size

M6

M8

M10

M12

M14

M16

Tightening torque (Nm)

15

32

62

108

170

262

Tightening torques for mounting the modules

(Screw quality 10.9)

Screw size

M4

M5

M6

M8

M10 M12 M14

Tightening torque (Nm)

4.2

7.5

13

28

50

88

120

4.8

Summary of Contents for VERO-S NSE plus 100-75

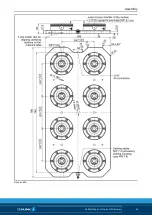

Page 32: ...Assembly 32 04 00 NSE plus NSL plus NSD plus en NSE plus 100 75 4 3 10 ...

Page 41: ...Assembly 04 00 NSE plus NSL plus NSD plus en 41 NSL plus 400 ...

Page 43: ...Assembly 04 00 NSE plus NSL plus NSD plus en 43 NSL plus 600 ...

Page 45: ...Assembly 04 00 NSE plus NSL plus NSD plus en 45 NSL plus 800 ...

Page 64: ...Assembly Drawings 64 04 00 NSE plus NSL plus NSD plus en NSE plus V1 cylindrical version 9 2 ...

Page 65: ...Assembly Drawings 04 00 NSE plus NSL plus NSD plus en 65 NSE plus 100 75 9 3 ...