Assembly

02|NSE-M plus 138 |en

13

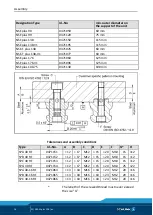

Positioning of the module can be done via two different centering

diameters of the installation area:

Ø 138H6

(upper area)

Ø 110H6

(bottom area) depending on the installation version.

The clamping system is suitable for partial or complete installation

Partial installation should be preferred.

An access bore to the actuation connection must be provided in

the installation space for the complete installation.

Make sure the hexagon socket of the actuating piston is easy to

access at all times. An access bore of sufficient size ensures that

the access to the hexagon socket is well visible.

If any chips are in the access bore or hexagon socket, they have to

be removed prior to actuation.

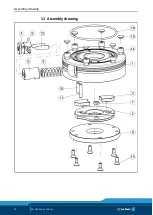

The clamping system is driven manually by rotating the drive

piston (item 4). The drive piston is laterally in the base body (item

1).

The drive piston (item 4) is actuated with a hexagon screwdriver

(angled pin wrench). Symbols, engraved on the base body, indicate

the direction of rotation for locking or unlocking the clamping

area.

No air supply is required for the operation of the clamping system.

The openings on the base side therefore do not have to be sealed.