Maintenance and care

20

02|NSE-M plus 138 |en

Maintenance and care

The Quick Change Pallet System is designed for minimum-

maintenance operation, so that opening and disassembly of the

clamping modules is only necessary in exceptional cases.

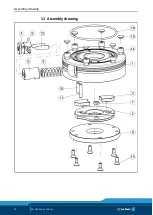

If it is necessary to disassemble the quick change pallet system,

this may only be performed by trained specialist personnel.

• Clean all parts thoroughly and check for damage and wear.

Damaged and worn parts must be replaced.

• Grease the sliding surfaces of the guide curves in the drive

piston with LINO MAX 200.

• Grease the sliding surfaces of all movable components with

Renolit HLT 2.

Replace damaged parts only with original SCHUNK replacement

parts!

A repeated functional check is to be conducted before the start-

up.

General operating conditions

• Make sure that the bearing surface of the interface is always

clean.

• Please arrange the necessary, so that chips of any type can’t

get into the interface. Moreover, please avoid that coolant

emulsion fills up in the interface, espacially if the axis of the

clamping pin is vertically aligned. Both can be avoided by using

a protection cover SDE 138.

If the interface should nevertheless fill with coolant emulsion,

start locking and dry the interface during actuation.

• For operation, only high-quality coolant emulsions with rust-

protection additions should be used.

• Regularly inspect the units (at least every 2 weeks or after 1000

clamping cycles). Perfect operation is given whenever the

clamping slides move smoothly without increased application

of force when actuated by means of the piston. Safe operation

also includes the self-locking of the clamping area.

• Regularly inspect the system visually and control proper

function. In case of visible damages or signs of malfunction,

please stop the operation immediately. The system should not

be started up again, before all the damages are repaired. I.e. by

exchanging the damaged unit.

8