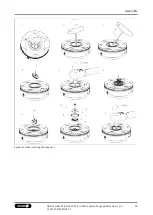

Assembly

44

08.00 | NSE3 138, NSE-T3 138 | VERO-S quick-change pallet system | en |

1152197 -NSE3 NSE-T3

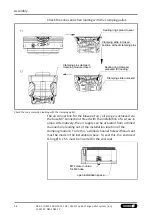

Observe the following when controlling the NSE3 and NSE-T3

quick-change pallet systems:

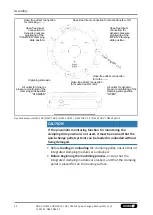

Turbo function:

• The actuating pressure for the turbo function must not exceed 6

bar.

Clamping slide monitoring with NSE3 99 and NSE3 138:

• The max. pressure for clamping slide monitoring is 2 bar.

• Limit volumetric flow to 15 l/min.

• Pressure difference upon failure of a module min. 1 bar.

Air purge / contact monitoring:

This function is used to monitor the face contact of the clamping

pallet that is clamped. A differential pressure switch must be used

for monitoring. When using the air purge as contact monitoring,

the sealing ring on the support side of the clamping module must

be removed carefully. This ensures that the escaping air purge can

escape up to the contact of the clamping pallet that is clamped

and a differential pressure measurement can be carried out.

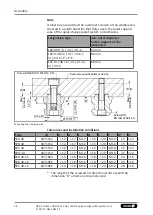

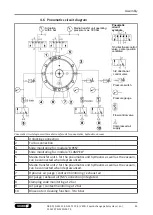

For NSE3 and NSE-T3, by incorporating the connection thread in

the center of the plug. For NSE3 99-K, NSE3 99-V1-K, NSE3 138-K,

NSE3 138-V1-K, NSE3 138-V4-K, centrally at the base via M7

connection thread: *

• Max. pressure 2 bar.

• Limit volumetric flow to 15 l/min.

• When using the air purge for contact monitoring, the sealing

ring on the support side of the clamping module must be

removed.

To guarantee a reliable evaluation, the pressure and air volume of

the air purge for monitoring face contact must be kept constant.

Pressure fluctuations can affect the settings of the differential

pressure switch and lead to incorrect measurement results. The

length and cross-section of lines can affect the switching time of

the control components. It may be necessary to readjust the

control components. Check the control components of the

monitoring functions at regular intervals. If errors occur in the

monitoring control system, you must detect the cause of the error.