Troubleshooting

54

08.00 | NSE3 138, NSE-T3 138 | VERO-S quick-change pallet system | en |

1152197 -NSE3 NSE-T3

8 Troubleshooting

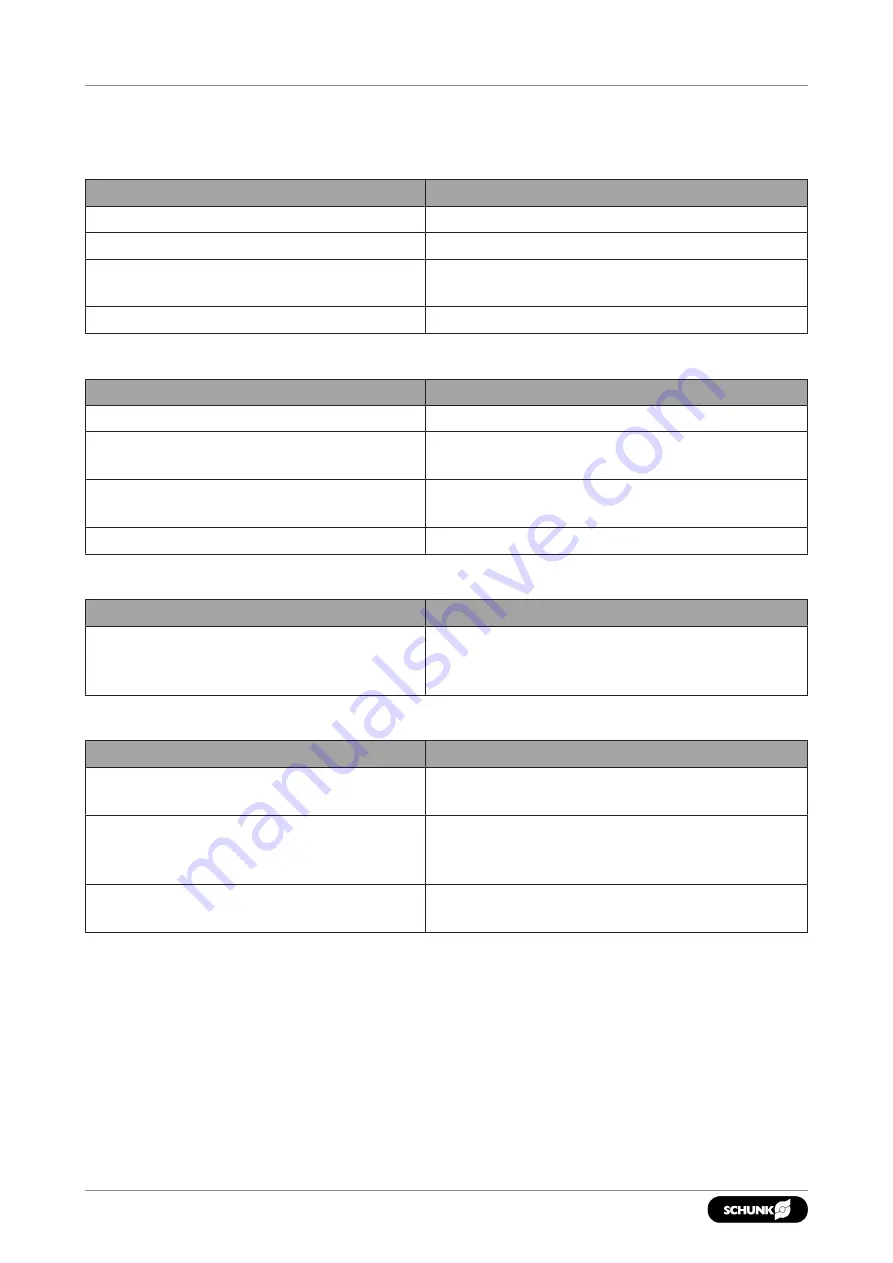

8.1 The clamping area does not unlock

Possible cause

Remedial measures

Defective air connections

Check air supply

Pressure below minimum

Check operating pressure (min. 5 bar)

A component is broken (e.g. due to

overloading)

Replace the module or send it to SCHUNK for

repair

Excess tensile load on clamping pins

Reduce support weight

8.2 The clamping area does not unlock properly

Possible cause

Remedial measures

Pressure below minimum

Check operating pressure (min. 5 bar)

The module was not operated with oiled

compressed air

Install maintenance unit with oiler

Hose diameter below minimum

Required hose diameters, see chapter

"Securing and connecting"

The turbo connection is still pressurized

Ventilate the connection

8.3 The quick-change pallet system no longer opens quietly

Possible cause

Remedial measures

The clamping faces on the clamping slides

and on the clamping pin are dirty

Remove the clamping pin and clean the

clamping faces on the clamping slides and on

the clamping pin

8.4 If the clamping area does not unlock properly

Possible cause

Remedial measures

Clamping pallet is not flat

Depressurize media transfer units, bleed supply

to transfer units

Clamping pallet is not flat

Increase the force applied to the coupling

connection until the flat contact surface of the

module has been reached

Clamping pallet is not flat

Check installation position of coupling

elements