Assembly

40

08.00 | NSE3 138, NSE-T3 138 | VERO-S quick-change pallet system | en |

1152197 -NSE3 NSE-T3

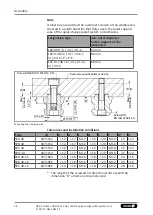

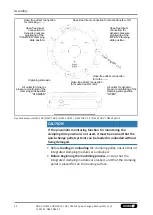

4.4.1 Information to clamping pin SPG 40

The SPG 40 can be used at a clamping area instead of the SPA 40.

If there are several clamping areas, only the clamping area with

clamping bolt type SPA may be exchanged for the SPG 40.

The repeat accuracy increases to < 0.002 mm when using the SPG

40.

When connecting the screws from above, a 10 mm longer M12

screw of strength class 12.9 must be used according to the

mounting option on the left in the illustration.

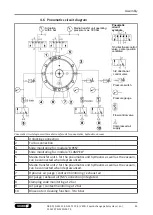

4.5 NSE3 Dynamic pressure monitoring of the clamping slide

position

The models NSE3 99, NSE3 99-K, NSE3 99-V1, NSE3 99-V1-K have

integrated dynamic pressure monitoring. With these, the

respective clamping slide position effects a build up of pressure in

the "OPEN" condition.

The models NSE3 138, NSE3 138-K, NSE3 138-V1, NSE3 138-V1-K,

NSE3 138-V4, NSE3 138-V4-K have two integrated pressure

sensors. With these, the respective clamping slide position effects

a build up of pressure in the "OPEN" or in the "CLAMPED"

condition. Either just one of the two monitoring functions or both

simultaneously can be used for alternative control monitoring.

Actuating clamping slide monitoring requires a reduced pressure

supply that is limited to 2 bar (see chapter "Pneumatic circuit

diagram"

).

The measurable differential pressure must reach a minimum of 1

bar for assessment via the air gap sensor to be reliable. The

maximum pressure is 2 bar. Monitoring requires a pressure

gauge, an adjustable throttle and an air gap sensor.

For clamping slide monitoring, the designated connection must be

actuated via a floor-side drilled hole.

Request our installation drawings if performing the installation

yourself.