Assembly

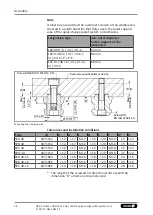

4.9 Dynamic pressure monitoring for workpiece planar contact

monitoring for NSE3-K, NSE-T3-K

With the NSE3 99-K, NSE3 138-K, NSE-T3 138-K, the cone seal can

be used for the workpiece planar contact monitoring.

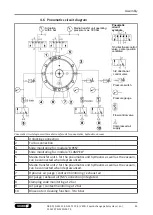

Step-by-step sequence of the function with series-connected

dynamic pressure monitoring of multiple modules.

Example with 2 modules:

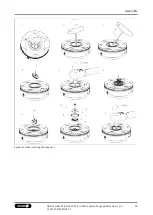

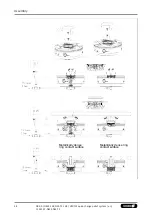

1. Remove the O-ring on the bearing surface of all clamping

modules intended for monitoring, use the O-ring assembly tool

for this.

2. Remove the countersunk screw on the cone seal.

3. Install the countersunk screw with ventilation hole. (Accessories

1403711)

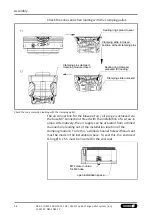

4. For clamped modules without clamping pins, actuate the

dynamic pressure monitoring for face contact monitoring air

purge → Pressure in the set range 2 bar, volumetric flow 15 l/

min → Low measurable differential pressure at the pressure

sensor.

5. Actuate clamping modules for loading in "open" condition

→ Differential pressure at the pressure sensor drops further.

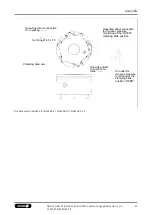

6. Insert the clamping pallet into the unlocked clamping areas.

7. Lock clamping areas by removing the pressure control

→ Differential pressure at the pressure sensor increases,

measurable dynamic pressure maximum 2 bar with full-surface

support of the clamping pallet at all support areas.

47

08.00 | NSE3 138, NSE-T3 138 | VERO-S quick-change pallet system | en |

1152197 -NSE3 NSE-T3