Wear parts set and parts lists

Parts list key

a =

For basic version for NSE3 138, NSE-T3 138

b =

For version with cone seal for NSE3 138-K,

NSE3 138-V1-K, NSE3 138-P-K, NSE-T3 138-K, NSE-T3 138-V1-

K, NSE3 138-V4-K, NSE-3T 138-V4-K

c =

For version with torque pin V1 for NSE3 138-V1,

NSE3 138-V1-K, NSE-T3 138-V1, NSE-T3 138-V1-K, NSE3 138-

V4-K, NSE-3T 138-V4-K

d =

Not for NSE-T3 138 and its versions

e =

Only for NSE-T3 138 and its versions

f =

Only for version with media transfer unit NSE3 138-P,

NSE3 138-P-K

g =

included in the sealing kit

h =

For version with V4 torque pin

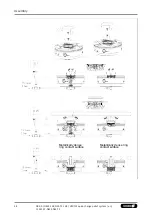

9.2.3 Cone seal KVS 40 (ID 1313742)

Item

Designation

Quantity

a

1

Mount

1

2

Thrust washer

1

3

Cover plate

1

4

Cover

1

5

Sealing ring

1

x

6

Compression spring

1

x

7

Countersunk screw

1

x

8

O-ring

1

x

9

O-ring

1

x

* 10

O-ring

1

x

* Component for sealing within the installation space for the

supply of blow-out air

a =

Included in the sealing kit.

59

08.00 | NSE3 138, NSE-T3 138 | VERO-S quick-change pallet system | en |

1152197 -NSE3 NSE-T3