Assembly

Reduced material thickness

in marked areas

Bore holes permitted in

shaded areas

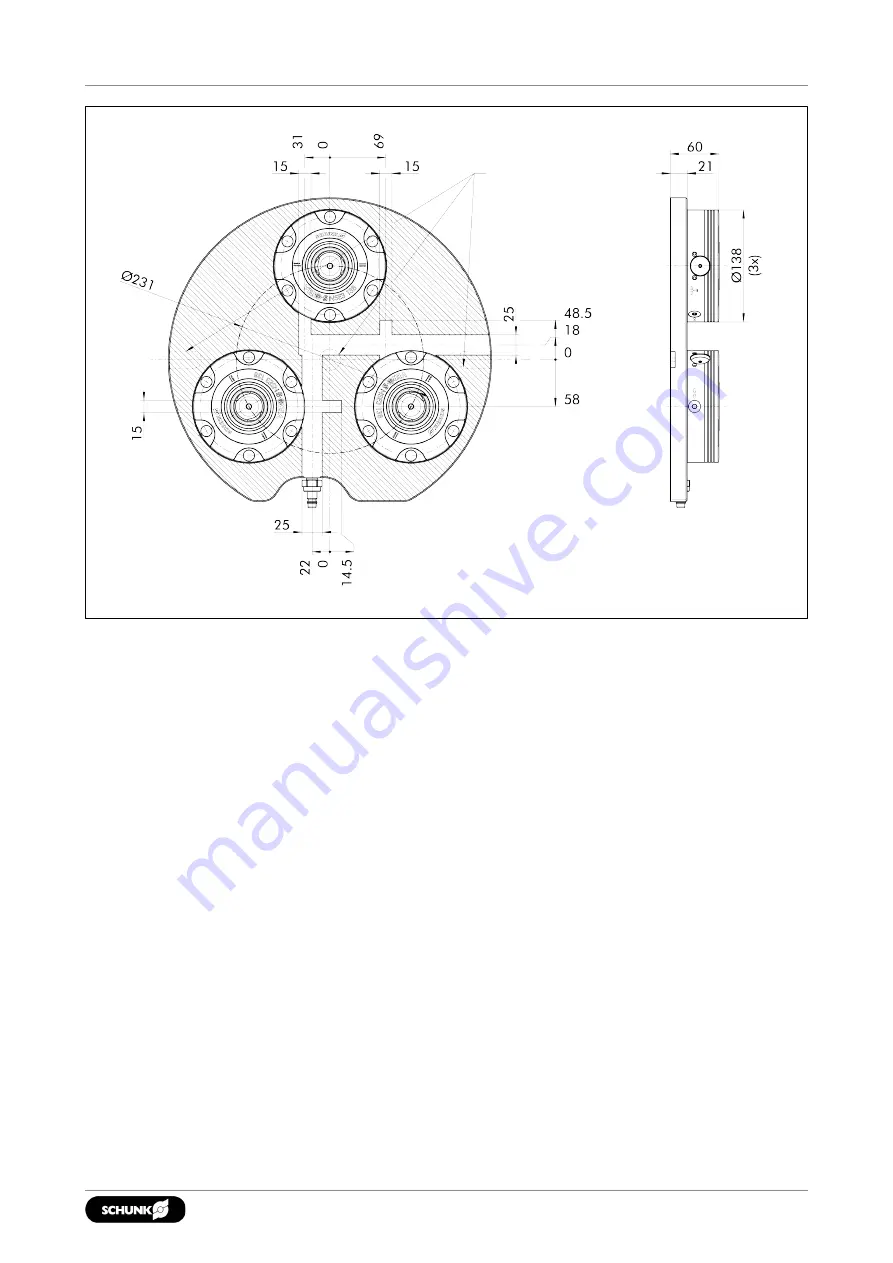

NSL3 300-200

4.3.5 NSL3 400

The clamping station can be clamped directly onto the machine

table via screws. Permitted areas for appropriate bore holes can

be found in the attached bore hole drawings. Optionally, BRR 50

clamp banks can be purchased. There are already 2 mounting

holes at a distance of 200. These mounting points are fixed

between the clamping modules, transverse to the operator side.

Size M10 screws can be used at the additional mounting points to

achieve a more rigid set-up when using clamps. There are two

alignment grooves on the bottom of the clamping station to

mount T-nuts used for aligning the clamping stations. These allow

for precise alignment along an alignment groove. The NSL3 400 is

equipped with two interconnected G 1/8" air connections for

simultaneously unlocking all four clamping points. The air supply

can be connected to either the front or the back of the clamping

station. The opposing connection point is closed with a locking

25

03.00 | NSL3 | VERO-S quick-change pallet system | en | 1155408