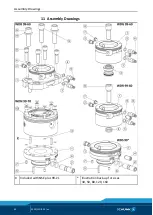

Functional description

46

02.00|WDB 99 |en

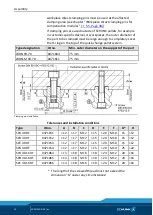

When changing an additional modular system component, the

tapered screw at the intake interface of a base module, basic

module or stacking module must be turned back clockwise until

the tapered tip of the screw does not protrude into the taper

mounting.

The contact surfaces of the clamping systems must be clean and

drive before changing. Make sure that the sealing elements for the

compressed air routing are not damaged. The change components

can now be changed into the unlocked intake interface. In doing

so, ensure that they are installed in the correct direction.

A cylindrical pin is intended as a guide.

The clamping systems can be fixed using the T-handle hexagonal

socket screw driver included. For clamping, the precise screw

tightening torque must be initiated at the clamping area. The

connection point is hereby fixed and positioned.

A tapered screw is included in the scope of delivery as a spare part.

Sequence when substituting a stacking module into the change

interface

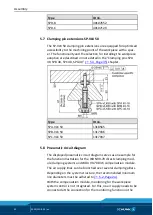

Functions of the air routings in the change components

The modular system for workpiece direct clamping is aligned for

the VERO-S NSE plus 99 pneumatic quick-change pallet system. For

air supply to the quick-change pallet module, the clamping sys-

tems have integrated air routings, which are controlled via a base

module or a basic module (see chapter "Pneumatic switching dia-

).

6.2