7.

Maintenance

7.1

General Information

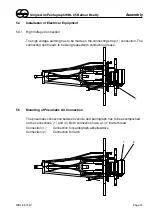

The Single Arm Pantograph WBL 85 requires less maintenance. At the regular

maintenance intervals of the vehicles, the following procedures are recommended:

During each inspection (max. 10000 km):

❍

Inspection of carbon strips (breaks, wear).

❍

Inspction of horns.

❍

Check proper function of signalhorn and contact force monitoring system.

Every year:

❍

Visual inspection of screws and shunts.

❍

Visual inspection of cable of raising mechanism, if needed, grease with

TOP 2000 of company AGIP Schmiertechnik.

❍

Inspection upward force, adjust, if necessary.

❍

Inspection easy motion of bearings, pan head springs, etc.

❍

Pneumatic equipment for leakages.

After max. 3 years:

❍

Grease the ends of the tow-rope with TOP 2000 of AGIP Schmiertechnik.

❍

Replace shunts.

After every 8 to 10 years and on any main inspection

(max. after 2000000 km / 1250000 miles):

❍

Change all ball bearing.

❍

Inspect for corrosion, if necessary replace coaling.

❍

Change rubber bumpers on base frame.

❍

Change leaf springs of pan head.

❍

Change cable of raising mechanism.

❍

Inspect/change of valve control unit.

❍

Change plain bearings.

❍

Replace all air tubes.

❍

Inspect/replace air bellow drive.

❍

Replace 3/2-way monitoring valve on pan head.

WBL 85-15kV

Maintenance

Single Arm Pantograph WBL 85 Balfour Beatty

Page 15

Summary of Contents for WBL 85 Balfour Beatty

Page 34: ......

Page 35: ......

Page 36: ......

Page 37: ......

Page 38: ......

Page 39: ......

Page 40: ......

Page 41: ......

Page 42: ......

Page 43: ......

Page 44: ......

Page 45: ......

Page 46: ......

Page 47: ......

Page 48: ......

Page 49: ......

Page 50: ......

Page 51: ......

Page 52: ......

Page 53: ......

Page 54: ......

Page 56: ......